Choosing the Right Touch Technology for your Industrial Display

An Introduction To The Industrial Touch Screen

Industrial touch displays are commonly used in both commercial and industrial settings for various applications and it’s likely you’ve interreacted with one already today. They are commonly used in kiosks for self-service terminals, making processes easier and reducing waiting times. Point-of-sale terminals in retail stores and restaurants also use touch screens for faster transactions and reduced errors. In industrial settings, touch screens are also used in factory floor human-machine interfaces, allowing operators to control and monitor industrial processes.

The available touch technologies for industrial settings are resistive touch, capacitive touch, infrared touch, and projected capacitive touch. Each technology has its own strengths and suitability for different industrial applications. The choice of touch technology depends on factors such as the specific requirements of the application, the environmental conditions, and the desired level of interactivity and durability.

With various touch technologies available how do you know which touch technology is right for your application? Before choosing your next industrial touchscreen monitor there are a couple of operational and environmental factors to consider to get the best performance and longest operation time in the field. You should consider the type of application, the environment in which the industrial touch monitor is being deployed, and the required performance of the HMI you are designing. A few important questions are listed below and shortly followed by the advantages and disadvantages of each touch technology which will help you decide which is best suited for your application.

What display size is suitable for your application?

How will the operator use the touch display? Finger, glove or alternative object?

What is the frequency of operation?

Will the touchscreen be deployed indoors or outdoors? Will the display need to be high bright or sunlight readable?

What are the required operating conditions? Will the touchscreen be exposed to bad weather or possible contamination?

Will the touchscreen be at risk of vandalism?

Touch Screen Solutions from Things Embedded

Interactive Displays

Digital Signage Kiosks

Resistive Touch Technology

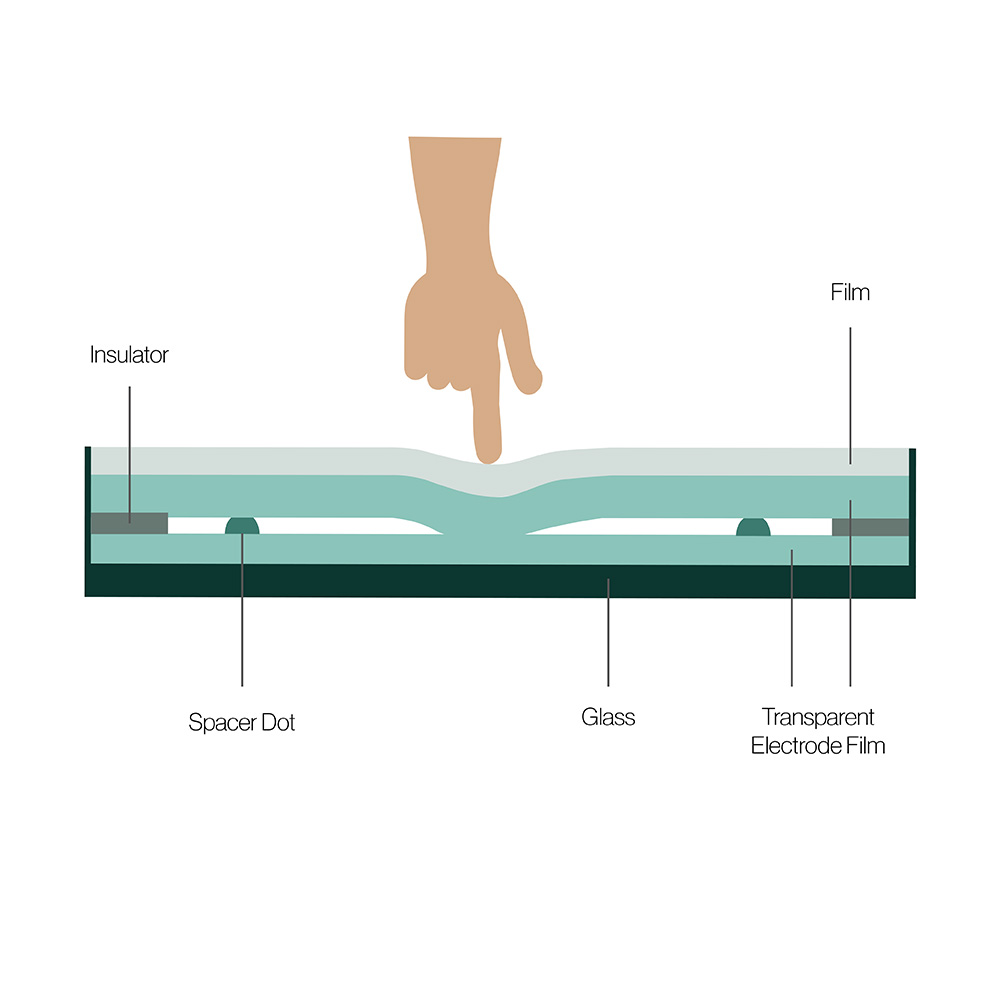

Well know in the industry, resistive touch technology was the most widely used touch technology. The resistive touch sensor is composed of a flexible transparent plastic front screen and rear glass or transparent panel with each layer having the inside surfaces covered in a thin metallic coating. The coating is typically made of Indium Tin Oxide and one layer will have a small measured charge applied. A slim air-gap, formed by minuscule glass beads, separates the plastic front display and the back glass. When the user interacts with the front display using their fingers or any solid item, the two metal layers beneath the point of contact connect, leading to an electrical current. Upon touch, a variation in voltage is identified. The touch controller connected then calculates and triangulates the activation point. With the resistive touch display being prone to damage once hit with force or scored into, these are best suited for well maintained, low cost, and low usage applications. With negligible electromagnetic interference these displays are suitable for military and medical applications.

Advantages of Resistive Touch Technology:

- Can be activated with any object such as your finger, stylus or glove.

- Mass produced touch technology available for low cost.

- Energy efficient with low power consumption.

- Wont be affected by vibration or surface contaminants.

- Negligible electromagnetic discharge (EMI).

- Option to be sealed from dust and water with IP65 protection for water resistant applications.

Disadvantages of Resistive Touch Technology:

- Lower light transmission compared to other touch technologies due to the application of conductive coatings.

- The external layer is susceptible to harm from scratches, jabs, and pointed items. Once damaged the localized area will stop working.

- Maximum size typically limited.

- Touch drift common among long term wear on the layers from repeated touching.

- Generally limited to single or dual touch control.

Surface Capacitive Touch Technology

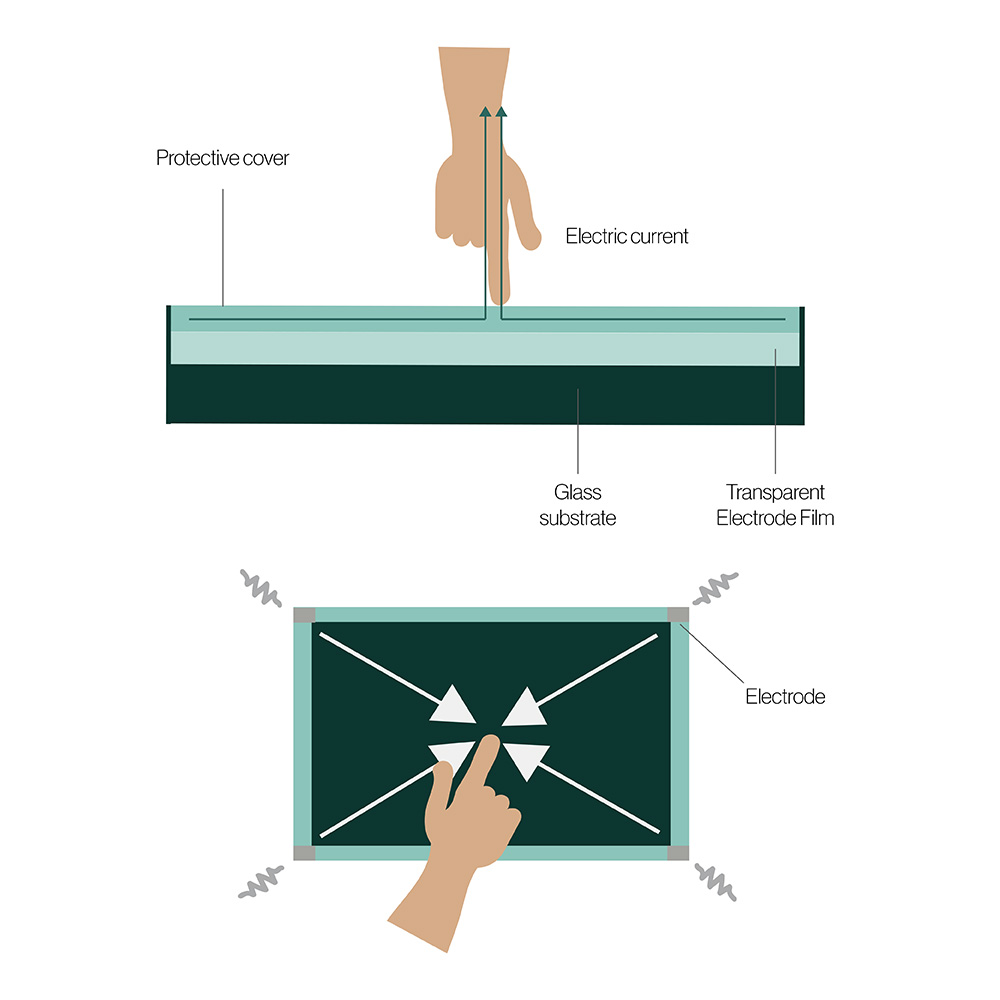

Surface Capacitive touch sensors are manufactured by coating a glass panel’s surface with an ultra-thin transparent conductive layer, typically made of Indium Tin Oxide. This layer is subjected to a minuscule, calculated electrical charge. When a bare finger or a conductive stylus comes into contact with the screen, a portion of the electrical charge is transferred from the screen to the user. Transducers situated at the four corners of the screen detect this reduction in capacitance, enabling the controller to pinpoint the touch location through triangulation. Surface Capacitive touch screens are most appropriate for supervised, indoor uses where durability is not a critical factor.

Advantages of Surface Capacitive Touch:

- Superior image quality compared to Resistive touch.

- Advanced technology, broadly accessible at a more affordable price relative to numerous other technologies.

- Impervious to surface grime and dust.

- Sizes up to ~32”.

Disadvantages of Surface Capacitive Touch:

- Requires bare finger or capacitive stylus for activation.

- Operation affected by damage and liquids on the surface.

- Affected by long term wear on the layers from repeated touching, which causes touch ‘drift’.

- Lacks support for multi-touch features.

- Transducers on the edge hinder the creation of completely flat touchscreen designs.

- Every touch sensor is ‘calibrated’ to its specific controller, which makes replacement expensive.

Projected Capacitive (PCAP) Touch Technology

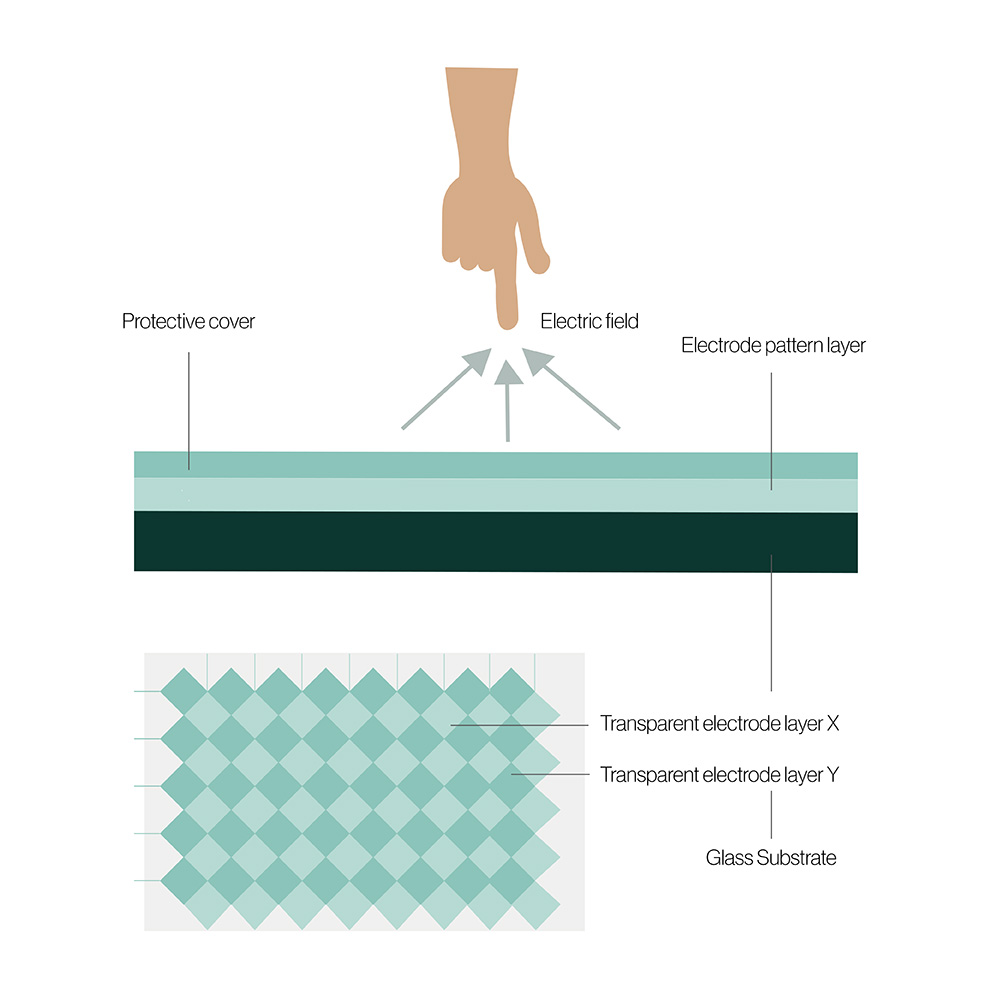

Projected Capacitance has surpassed Resistive as the leading touch technology worldwide. Similar to Surface Capacitive touch detection, Projected Capacitive technology depends on a conductive object interacting with the screen’s charge, but it provides significant benefits as outlined below. A projected capacitive touchscreen consists of a front panel made from see-through material (typically glass) with a grid of transparent electrodes, arranged in an X-Y pattern, either layered or fixed to the back. When these layers receive a charge, a three-dimensional electrostatic field is created around the touchscreen. As a finger or a conductive stylus nears the screen, a capacitive interaction occurs between the object in contact and the sensor. The touch controller then pinpoints the touch location within the grid by identifying the point of maximum variation.

Advantages of PCAP Touch:

- The display brightness and image clarity remains very good.

- Excellent resistant to scratching and impact damage, especially with thicker, toughened glass variants.

- Generally, unaffected by most surface contaminants and liquids (dust, grease, water droplets).

- Capable of working in all weather conditions when suitably designed and with a suitable touch controller.

- True multi-touch functionality available.

- Can work with gloved hands supporting capacitance.

- Depending on the conductive materials and controller used, suitable for large format displays.

Disadvantages of PCAP Touch:

- Typically, more expensive than other methods.

- More sensitive to electromagnetic interference.

- More attention to integration required.

Surface Acoustic Wave (SAW) Touch Technology

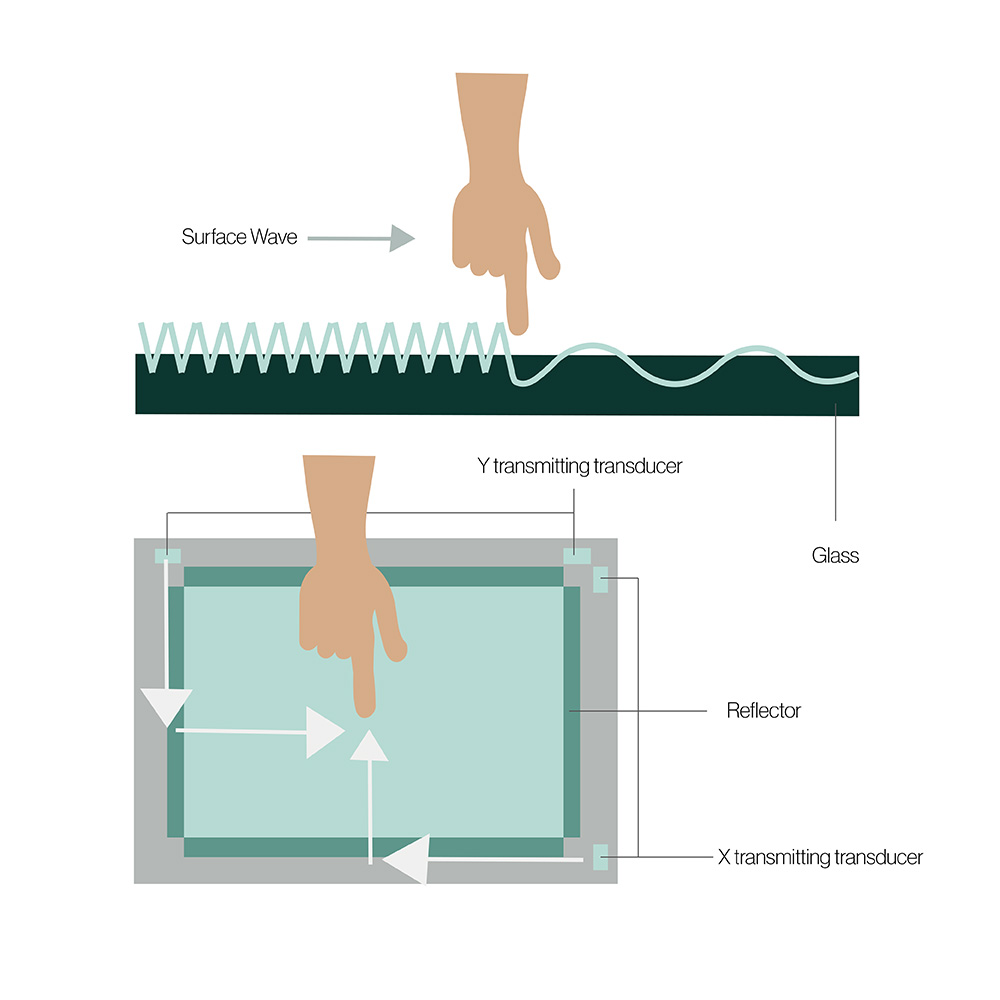

A constant ultrasonic wave is generated on the leading surface of the touch panel using a sequence of piezoelectric transducers and receivers positioned along the edge of the glass panel. This is known as Surface Acoustic Wave, or alternatively SAW touch technology. When a touch point is created on the front panel a portion of this ultrasonic wave is absorbed and the onboard transducers which are connected to the touch controller triangulate and locate the users touch point.

A SAW touch display is best suited for indoor use. Known for high scratch resistance and durability, SAW monitors are not very well suited to outdoor applications as their functionality can be negatively affected by surface contaminants and adverse weather conditions.

Advantages of SAW Touch:

- Can be operated with or without gloves, or alternatively a soft-tip stylus.

- Excellent image clarity as the glass panel contains no conductive coatings.

- Operation not effected by most scratches.

- Increase endurance to wear and tear.

Disadvantages of SAW Touch:

- Can not be operated with hard items such as a pen or fingernail.

- False-triggering caused by water droplets.

- Leftover residue on the screen can create non-touch areas until they are removed.

- HMI left prone to ingress of dust and liquid as the SAW touch panel cannot be sealed in order to allow free movement of acoustic wave at the edges of the screen.

- Known to be affected by shock and vibration.

- Limited to single and dual touch operation.

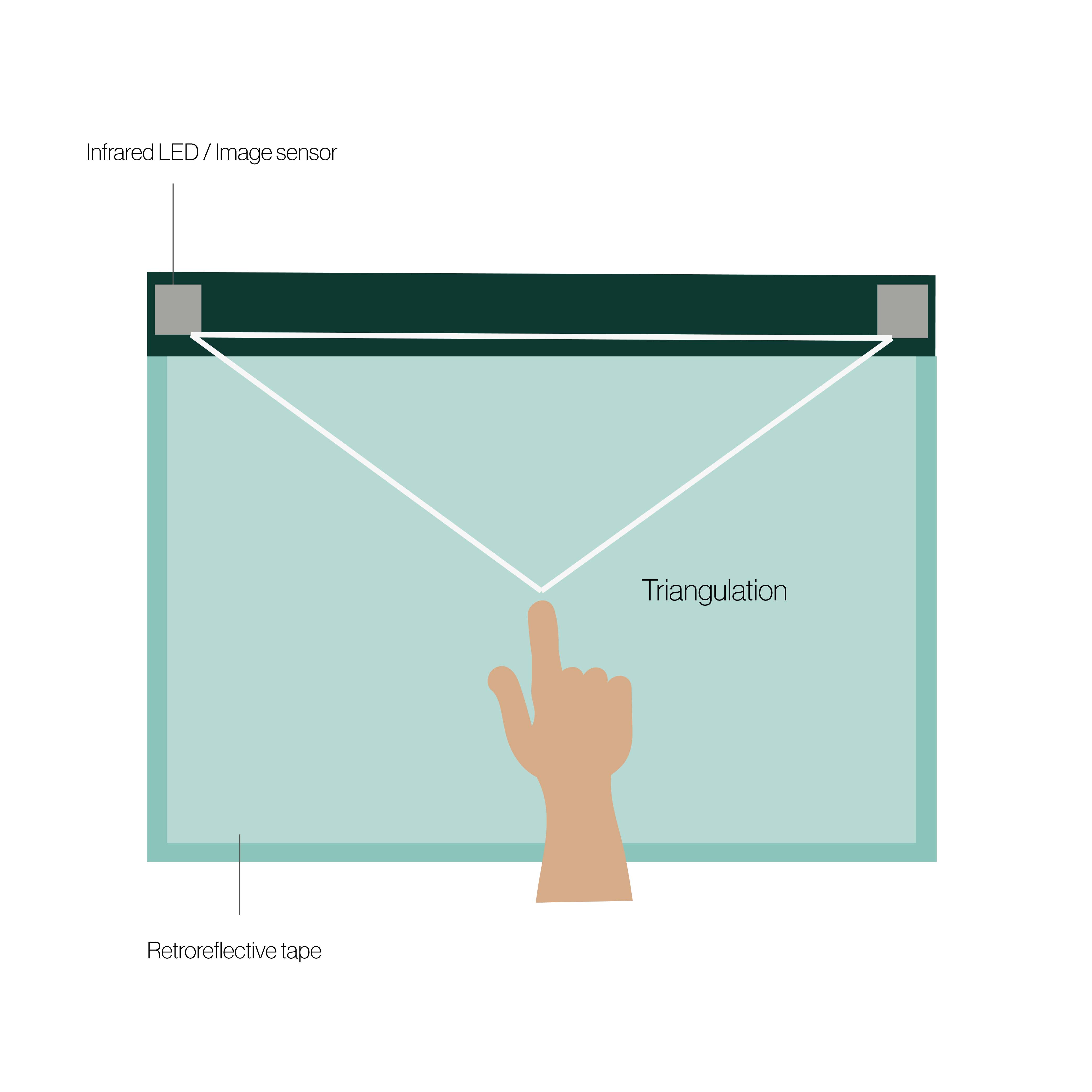

Infrared (IR) Touch Technology

Contrary to the majority of touch technologies, Infrared or “IR” touch screens don’t necessitate a touch-detecting overlay on the front of the display. They employ IR transmitters and receivers housed in a frame, typically made of plastic, which is affixed to the display bezel. This framework generates an unseen barrier or lattice of light rays across the display, from one side to the other and from the top to the bottom. When an object disrupts the infrared barrier, the touch controller identifies the touch location based on the X-Y coordinates of the disrupted signal. Occasionally, a safeguarding glass or plastic shield is positioned over the screen to avert any harm to the delicate LCD surface caused by touches.

Infrared touch technology is best suited for monitored and properly managed indoor uses where a large or cost-effective touchscreen is needed and the risk of frame impairment or pollution is minimal. Infrared touch technology is not ideal for outdoor use because its touch functionality can be significantly impacted by environmental light and weather circumstances.

Advantages of IR Touch Technology:

- Absolute display brightness and image clarity unaffected by the IR touch controller.

- Suitable for very large size displays up to 100”.

- With the correct IR touch controller the display can operate multi-touch.

- A low cost and mass market technology.

- Simple integration and replacement if failure.

Disadvantages of IR Touch Technology:

- Flat frame design not possible as the IR frame must stand higher than the display surface.

- Interference from any ambient light containing the IR spectrum such as sunlight will cause interference.

- Breaking the infrared beams will trigger a touch and allow for accidental activation.

- Build-up of dust and contaminants on the chassis frame will impede the light beams and cause touch malfunction or make it non-operative.

Want to discuss the best technology for your next industrial touch display?

Tell us about your application and a member of our team will get right back to you.