Installing an Industrial Fanless PC for Reliable Performance

This guide outlines the essential considerations for installing an industrial fanless PC, including effective heat management, the importance of a dedicated power supply, and strategies for thermal monitoring.

Every edge computing application comes with its own unique requirements, and extensive effort has been dedicated to choosing and configuring the ideal fanless computer for your project. These guidelines provide a solid foundation to help you implement best practices for installing your industrial fanless PC. If you want to explore how fanless computers operate and the benefits of passive cooling, we have all the information you need to get started.

An industrial fanless PC is engineered to provide reliable performance in challenging environments, making them an ideal solution for applications that require rugged durability, energy efficiency, and minimal maintenance. These solid-state systems leverage advanced passive cooling techniques, such as heatsinks and conduction cooling, to maintain optimal operating temperatures without the need for moving parts, enhancing reliability in harsh conditions. Proper installation is critical to ensuring these systems operate at peak efficiency. Adequate spacing around the PC for natural airflow, correct orientation of heatsinks, and consideration of the thermal properties of the surrounding environment are all essential. Whether deployed in tightly enclosed spaces, outdoor environments, or high-performance edge computing scenarios, a fanless PC equipped with passive or conduction cooling technology delivers ultimate reliability in today’s demanding industrial and edge computing applications.

Industrial Fanless PC Installation

Passive cooling with heatsinks serves as a fundamental pillar of fanless industrial PC design, efficiently dissipating heat generated by the system's internal components. Heatsinks are typically made from thermally conductive materials like aluminium and feature fins to maximise surface area, allowing heat to dissipate naturally through convection.

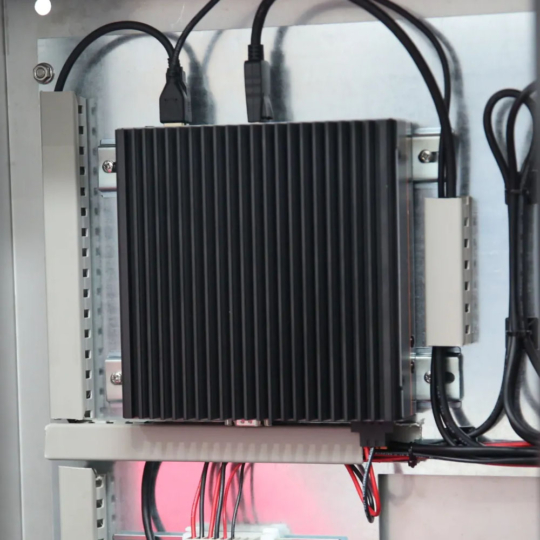

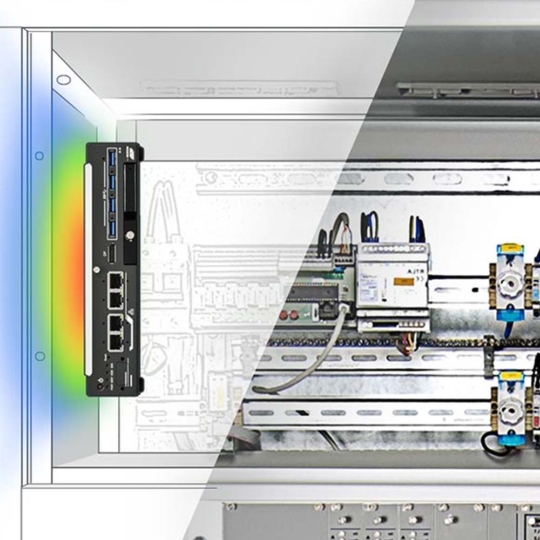

Fanless PC using Conduction Cooling Installed

Fanless PCs with heat spreaders leverage conduction cooling to optimize thermal management within an enclosure, efficiently transferring heat from key components like the CPU or GPU to the external environment. This method ensures uniform heat distribution, eliminates hotspots, and maintains reliable performance, even in compact or sealed spaces.

Installing an Industrial Fanless Computer

When installing a fanless industrial computer inside an enclosure, such as an unventilated industrial cabinet, or the trunk of a vehicle, ambient temperatures can quickly exceed the surrounding environmental temperature. While our fanless industrial PCs are highly energy efficient, ensuring sufficient clearance around the system is crucial for optimal performance. Adequate space allows airflow over the heatsink fins, promoting effective heat dissipation.

While setting up a your fanless IPC, it’s essential to consider that heat rises. Avoid placing other heat-producing equipment directly below the industrial PC, and ensure there is ample airflow above the system to facilitate natural convection over the heatsink fins. Stacking additional equipment, regardless of whether it emits heat, can obstruct airflow, reducing cooling efficiency and potentially leading to CPU throttling or long-term system damage.

For optimal cooling, the heatsink fins should face upwards when installing the industrial fanless computer inside the cabinet, enabling maximum heat dissipation. While installation on the topside of an enclosure with the fins facing downwards is possible, it significantly impacts cooling efficiency and should be monitored carefully to prevent overheating.

Best Practices for Installing a Fanless PC

- Carefully consider where you install the fanless PC. - Install the computer with heatsinks facing the “right” way. - Check system temperatures once installing and operating. - Consider additional environmental factors to shield the PC.

Common Mistakes to Avoid When Installing a Fanless Computer

- Avoid placing any items on top of your fanless PCs. - Don’t install your IPC in a fully enclosed area if temperatures get too high. - Ensure secure connectivity with proper cable management.

Protect Your Fanless Industrial Computer from Overvoltage, Overcurrent, and ESD with a Dedicated Power Supply

When powering a fanless industrial computer, it is highly recommended to use its own dedicated power supply whenever possible. This ensures the computer’s input remains independent from other equipment, maintaining optimal performance, reliability, and protecting against potential electrical interference. Sharing a common DC source with inductive loads, such as solenoids, relay switches, or motors, can introduce reverse voltage spikes, which pose a significant risk of damaging or even destroying the computer.

A dedicated power supplies offer a stable and isolated power source for your fanless industrial PC when operating in austere environments. Using a dedicated power source minimises the risk of voltage fluctuations and electrical noise, which can affect sensitive electronic components. If you need to share a power supply, it is essential to verify that the industrial computer is equipped with adequate DC power protection. Without proper safeguards, shared power sources can expose the system to risks associated with inductive loads or other equipment drawing from the same power line. Investing in a dedicated power supply ensures not only the longevity of your equipment but also peace of mind when operating in environments with potential electrical challenges.

Our fanless industrial PCs are available with protection against overvoltage, overcurrent, and ESD protection. Many models feature a wide DC input range, typically from 9 to 48V DC, enabling them to handle power dips and surges more effectively than an industrial PC with a fixed 12V or 24V DC input. This broader input range makes them more adaptable to variable power conditions, offering greater reliability for both industrial and edge computing.

Effective Thermal Monitoring for Your Fanless IPC

Thermal monitoring is a critical aspect of maintaining the performance and longevity of your fanless industrial PC, especially when installed in a confined or sealed enclosure. By continuously tracking the internal and external temperatures of the embedded system, thermal monitoring helps detect potential overheating issues before they can cause the system’s performance to throttle, or lead to system failure.

Once the fanless IPC has been installed and is operating, the system should be warm when touched. This is a good side that the passive cooling mechanism is working and doing its job effectively. Using infrared technology, you can take a temperature measurement from the chassis to make sure the dissipated heat isn’t excessive as this can indicate an issue and may cause your CPU to throttle.

Modern CPUs and GPUs integrated within industrial computers often provide real-time temperature readings, enabling proactive adjustments to operating conditions, such as reducing processing loads or enhancing airflow. Traditional fanless industrial PCs with external fans for assisted cooling offer a hybrid approach to thermal management, combining the solid-state reliability of passive cooling, which protects sensitive internal components, with the enhanced heat dissipation provided by active airflow. This setup is particularly effective, and sometimes essential, for high-performance computing applications in demanding edge environments.

Have Further Questions About Installing a Fanless Computer?

Tell us about your application and a member of our team will get right back to you.