Why Can Industrial M12 Waterproof Connectors Be Critical In Harsh Environments?

Circular M12 connectors are integrated into a wide range of industrial computers, panel PCs, industrial displays, and ethernet switches used in harsh environments such as the food and beverage or transportation industry. In such applications, it is imperative to have rugged connections for power, signal and data communication in order to withstand shock and vibration or mechanical stress, dust and water ingress, and resistance to chemical applications.

The flexibility and mechanical qualities of industrial M12 connections are undoubtedly the factors that have determined its success in providing long life industrial computing solutions. They can in fact be used to cover all the physical wiring needs of devices, and are widely used for chemical and washdown applications, outdoor edge based industrial IoT (IIoT), and rugged computing.

What Is An M12 Connector?

An M12 connector is a standardized circular connector commonly used in industrial applications. With a 12mm locking thread, it’s designed to withstand harsh environments and provide secure connections for various tasks such as power, signal, and data transmission. Available in different coding types like A, B, D, and X, each with specific pin configurations, M12 connectors are utilized in areas like manufacturing, transportation, and automation, where reliability and robustness are essential.

Industrial Compute, Control and Communication with Rugged Waterproof M12 Connectors

Benefits of Industrial M12 Waterproof Connectors

Industrial M12 waterproof connectors are an essential component in today’s demanding industrial landscapes. With their rugged design, impermeable nature, protection against electromagnetic interference, and ease of integration, they offer a robust solution for environments where conventional connectors might falter. By adopting M12 connectors, industries can achieve reliable and continuous operation, enhancing efficiency and reducing the risk of unexpected shutdowns.

The use of industrial computing equipped with M12 type connectors guarantees precisely the type of protection necessary for these types of environments. An industrial M12 connector provides the following characteristics:

Rugged Connectivity

M12 industrial connectors are designed to endure the rigors of both outdoor applications and harsh factory environments. This encompasses a wide array of challenges, including mechanical stress from shock and vibration, temperature extremes from freezing to sweltering, radiation, exposure to corrosive chemical agents, and more. Such rugged connectivity ensures that even in the face of these environmental adversities, the connection remains intact and functional, allowing continuous operation of the equipment without interruption.

Impermeable to Water and Dust Ingress

M12 connectors offer various levels of protection against water and dust ingress, depending on the specific IP rating. For example, IP67-rated M12 connectors can withstand immersion in water up to 1 meter deep for 30 minutes, making them suitable for wet and damp environments. On the other hand, IP69K-rated M12 connectors can resist high temperature and high-pressure water jets, making them essential in applications such as food processing, where high-pressure washdowns for sanitization are common. This range of protection allows the connectors to be tailored to the specific needs of the environment, providing precise shielding against potential hazards.

Protection from Electromagnetic Interference

In industrial settings, electromagnetic interference (EMI) and radio frequency interference (RFI) can be significant problems, disrupting communication and causing malfunctions in sensitive electronic equipment. Some M12 connectors come equipped with special shielding to mitigate this issue. By blocking unwanted electromagnetic and radio frequency signals, these connectors preserve the integrity of the data being transmitted, ensuring reliable and accurate communication. This is crucial in complex industrial systems where precision and coordination among various components are paramount.

Simple Integration with Easy Assembly

M12 connectors are designed with ease of integration and assembly in mind. Whether utilizing traditional screw-type connections or other methods, they can be assembled effectively even in challenging conditions. The standardization of M12 connectors, available in various codings like A-code or X-code and different genders, ensures compatibility across devices. With specified pin-outs for signals and power, they support common industrial interfaces like Ethernet, USB, Serial, and CAN, promoting straightforward integration. This flexibility simplifies the design, installation, and maintenance process, saving time and reducing the likelihood of errors.

Common Industrial M12 Codes

M12 A Coded Connectors

These are perhaps the most common type of M12 connectors, widely used in connecting sensors and actuators in industrial environments. They typically come with 2, 3, 4, 5, or 8 pins, allowing them to handle various power, signal, and data transmission tasks. The A-code design ensures that they can only mate with corresponding A-coded receptacles, preventing connection errors. The rugged design, including IP67 or higher rating, ensures that they can operate reliably in challenging conditions, resisting factors like moisture, dust, and vibration.

M12 B Coded Connectors

Specifically designed for fieldbus connections, the M12 B-code connectors usually feature 5 or 8 pins. They are frequently used in applications such as PROFIBUS, one of the standard industrial communication protocols. The B-code design ensures compatibility with corresponding devices, promoting a standardized connection. Like other M12 connectors, the B-code variant is designed to operate in harsh industrial conditions, ensuring reliable data transfer even in demanding environments.

M12 C Coded Connectors

The M12 C-code connectors are less common compared to the A and B types but have specific applications in certain sectors. The exact details of the C-code design might vary, and its applications are specialized, so it is essential to consult specific documentation or manufacturer’s guidance to understand where this type might be best suited. Despite its niche status, the C-code variant shares the same robust characteristics typical of M12 connectors.

M12 D Coded Connectors

The M12 D-code connectors are tailored for Ethernet and PROFINET connections, especially in industrial automation. With a 4-pin configuration, these connectors typically support data rates up to 100 Mbps. The D-code design ensures proper mating with corresponding devices, fostering a reliable connection for data communication. Like other members of the M12 family, these connectors are ruggedly designed to withstand the harsh conditions common in industrial settings.

M12 X Coded Connectors

The X-code variant of the M12 connector is specifically designed to support Gigabit Ethernet applications. With 8 pins, these connectors facilitate high-speed data transmission, essential for modern industrial processes that require rapid and reliable data exchange. The X-code design ensures correct mating, reducing the risk of connection errors, while its robust build quality enables it to perform consistently even in environments that are prone to moisture, dust, or vibration. This makes the M12 X-code connectors a favored choice for applications demanding higher bandwidth and industrial-grade reliability.

M12 Connector Dimensions

M12 connectors are named for their 12mm locking thread, but the overall dimensions can vary based on the specific design, pin configuration, and manufacturer. Here’s a general overview of M12 connector dimensions:

Thread Size: As the name suggests, the M12 connector has a thread size of 12mm.

Pin Diameter: The pins themselves often have a standard diameter of around 1mm.

Housing Diameter: The outer housing diameter may vary, typically falling in the 14-16mm range.

Length: The length of the connector can vary widely based on design and intended application, ranging from approximately 40mm to 70mm or more.

Since M12 connectors are used in various applications and come with different coding’s and pin numbers, specific dimensions might differ. Always refer to the manufacturer’s datasheet for the exact dimensions of the particular M12 connector you are dealing with, as variations can be critical to proper fitting and functionality in specific applications.

M12 Male Connectors, M12 Female Connectors, and M12 Adaptors

The precise application, coding, and gender must be considered when selecting M12 connectors and adaptors, ensuring compatibility and reliable connections in the demanding environments typical of industrial applications. Always refer to the specifications and guidelines provided by manufacturers when selecting and using these connectors. M12 connectors come in both male and female types, and understanding the differences between them is vital for ensuring proper connections in industrial applications. Here’s a detailed breakdown:

M12 Male Connectors

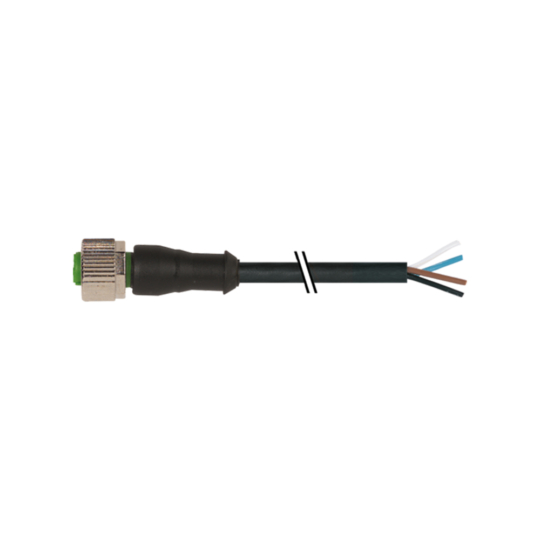

Male M12 connectors are characterized by their protruding pins, which are designed to snugly fit into the corresponding sockets of a female connector. These are commonly known as “M12 plugs.” In most scenarios, male connectors are found on the cable side and are used to connect to devices or panels equipped with female connectors. By mere observation, the male connector stands out with its exposed pins, seamlessly fitting into the female receptacle.

M12 Female Connectors

Female M12 connectors come equipped with sockets or receptacles specifically designed to accommodate the pins of a male connector. They are frequently referred to as “M12 jacks” or “M12 receptacles.” You'll typically find these female connectors on devices, panels, or on the opposing end of a connection where they are primed to accept male plugs. By appearance, the female connector can be easily identified by its distinctive sockets or holes that are designed to receive the pins of the male connector.

M12 Adaptors

M12 adaptors serve an essential role when there's a need to connect various types or genders of connectors. Gender changers are particularly useful as they permit the connection of two male or two female connectors by altering the gender of one end. On the other hand, coding adaptors are beneficial when there's a necessity to link two different coding types. Even though this is a less frequent scenario, it is crucial to proceed cautiously to prevent erroneous connections. Additionally, Y or T adaptors are available for those instances where there's a requirement to split a connection, making it possible to have one input and multiple outputs, or the other way around.

Require M12 Cable Assemblies?

Tell us about your application and a member of our team will get right back to you.