Importance of High Ingress Protection: IP65, IP66, IP67, IP68, IP69K

Ingress protection, also known as IP, is a rating system used to classify the level of protection against dust and water intrusion. The ratings are determined by tests conducted under specific conditions assigned by the International Electrotechnical Commission (IEC). The IEC is a global organization that develops international standards for electrical, electronic, and related technologies.

Standardized IP rating systems are important because they help industries to choose the right electronic equipment for their needs. Rugged computing and displays with a higher IP rating will typically be more expensive, but it will also be better protected against damage from dust, water, and other corrosive materials.

Industrial computers and displays are assigned IP ratings determined by tests conducted under specific conditions, in result two numbers classify the level of protection against solids and liquids. The first number rates the level of protection against solid objects, such as dust. The second number rates the level of protection against liquids, such as water. The industrial computer industry uses the IP rating system to classify the level of protection against dust and water intrusion for computer equipment because the electrical components onboard can be easily damaged by dust and water present in many industrial applications.

The necessary IP rating for a computer is entirely contingent on the industry and usage it is intended for. The type of environment the waterproof computer or waterproof display will be deployed in will typically define the level of ingress protection required to guarantee that it will operate reliably 24/7, even in harsh conditions. Things Embedded provide an extensive selection of industrial computing, display, and communication equipment for IIoT, all of which are prepared to operate dependably in various harsh conditions where water resistant or full waterproof protection is a must. We can assist in evaluating your industry conditions and determining how much protection is required ensure the chosen hardware will have a long operating life.

Waterproof Computers, Displays & Communication

Waterproof Panel PCs

Waterproof Displays

Waterproof Computers

Waterproof Ethernet Switches

IP Ratings Table

IP ratings are structured with two digits, like this: IPXX. The initial digit signifies the level of protection against solids, while the subsequent digit indicates the level of protection against liquids. In industrial and outdoor applications, it is vital to understand IP55 vs IP65 vs IP66 vs IP67 vs IP68 vs IP69K. Here is a quick summary using a computer as an example:

IP55: The computer is protected from a high-degree of dust ingress and can handle some exposure to water.

IP65: The computer is dust-proof and protected from splashes or low-pressure jets.

IP66: The computer is dust-proof and protected from strong water jets.

IP67: The computer is dust-proof and protected from temporary immersion in water 1 meter deep for 30 minutes.

IP68: The computer is dust-proof and protected from continuous immersion in water under more severe conditions.

IP69K: The computer is dust-proof and protected from water during high-pressure and steam cleaning, however, it is not submersible.

Industrial Applications Requiring Rugged Computers with High Ingress Protection

Food and Beverage Processing

As the food and beverage industry relies more heavily on computer-based control systems, they must also meet increasingly strict regulations for safety. Operations require heavy wash downs or high temperature water treatment with strong disinfectants when cleaning all equipment within the facility. To ensure all control systems are protected at all times, food and beverage operations need to install industrial hardware with a minimum IP65 rating for exposure to light spraying. Whereby heavy washdowns are considered to remove stubborn debris IP69K is a must have.

Marine, Military, and Outdoors

Rugged operation is a complete necessity when placing computers in harsh environments like on ships, outside or military vehicles. The computer will be exposed to water and dirt but also requires protection from corrosion from saline environments which can cause expensive damage over time if not dealt with properly. For outdoor applications exposed to rain then IP65 or IP66 protection will be suffice. Whereby there is risk of submersion or flooding, such as within the Maritime industry, IP67 is a must have.

Digital Signage

Digital signage applications requiring water ingress protection are commonly found in outdoor environments exposed to rain, humidity, or splashes. With a robust IP65 or higher rating, these digital displays ensure uninterrupted operation even in wet conditions. From outdoor advertising displays in bustling city centers to interactive information kiosks at water parks, these protected digital signs offer vital information, advertisements, or entertainment while safeguarding against water damage. Whether enhancing customer experiences or disseminating crucial information, water-resistant digital signage remains a reliable choice for effective communication in various outdoor settings.

Heavy Manufacturing and Industrial Settings

Front IP65 HMIs are commonly used in warehouses and factories to control processes as well as communicate with machinery. These rugged interfaces, designed with a robust IP65 rating, shield sensitive electronics from the ingress of dust, dirt, and potential splashes. Whether on factory floors, manufacturing lines, or processing plants, these HMIs provide workers with reliable and intuitive control while enduring the harsh conditions of heavy industry.

Pharmaceutical

In pharmaceutical applications, the need for ingress protection is paramount to maintain product integrity and regulatory compliance. With stringent hygiene standards, controlled environments, and potential exposure to dust and moisture, pharmaceutical equipment and enclosures often require high IP-rated protection. Devices like cleanroom PCs must adhere to completely dust tight standards to prevent contamination and ensure efficient operation in sanitized conditions. Equipment used in this field is very advanced, so it’s necessary you have clean rooms with limited air pollution and no foreign objects, making a fanless solution a must have.

What is IP65?

IP65 computers and displays provide a high degree of waterproof protection for wiping downs, light wash-downs from low pressure water jets and outdoor applications where rain or dripping water is present. The IP65 ingress protection standard has been widely adopted by multiple industries, particularly for displays and panel PCs.

IP65 Meaning

The first digit (6) indicates protection against solids: A rating of 6 means the device is “dust tight,” indicating it offers a high level of protection against the ingress of dust and other small solid particles. The device’s enclosure is designed to prevent most dust from entering and potentially damaging internal components.

The second digit (5) indicates protection against liquids: A rating of 5 means the device is “protected against water jets.” This implies that the device is designed to withstand the impact of water projected by a nozzle from any direction. The water projected is not powerful enough to cause harmful effects or penetration.

Front IP65 vs Full IP65

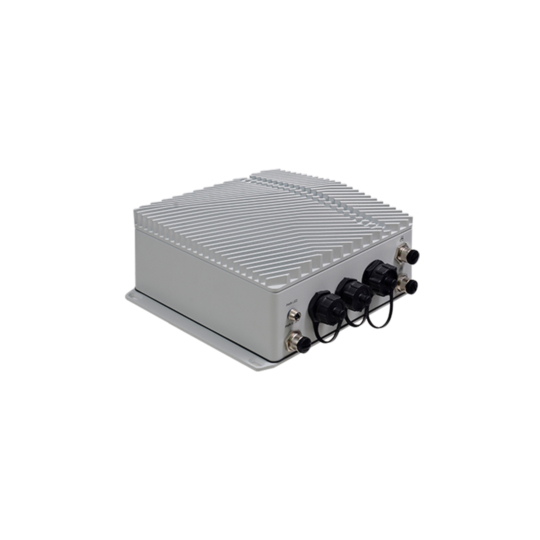

You may notice that our range of IP65 monitors and IP65 panel PCs are available in a panel mount form factor. These panel mount solutions are designed to be installed in an open aperture whereby a rubber seal protects any ingress from getting to the back side of the system. For this purpose you will see industrial PC manufacturers list their panel mount displays and Panel Mount PCs as either Front IP65 or Full IP65. A front IP65 solution would be tested to the IP65 test specification when installed in the open aperture from the front side of the display only. A full IP65 solution undergoes testing from all six sides, meaning the back side of the system where I/O and opportunities for ingress with standard connector types is present. An industrial full IP65 solution will typically utilize M12 waterproof connectors to maintain the IP65 standard.

IP65 Test Specification

Both Front IP65 and Full IP65 industrial PCs and displays undergo a stringent set of challenging tests to ensure that they are waterproof and dust tight. Here are the following testing procedures carried out on our IP65 solutions:

- The system is positioned on a rotating platform that completes a full rotation every 12 seconds, the equivalent of 5 revolutions per minute.

- The water pressure is set low.

- The nozzle with a 6.3mm diameter is held 2.5-3m from the tested device at angles of 0, 30, 60 and 90 degrees for 30 seconds each.

- The system is sprayed with a flow rate of 12 litres (3.5 gallons) per minute.

Is IP65 Suitable For Outdoor Use?

IP65 is generally considered suitable for outdoor use in many scenarios and offers a high-degree of weather resistance. The IP65 rating provides a good level of protection against dust and water, making devices with this rating suitable for outdoor environments where they might be exposed to various weather conditions. If the device is going to be subjected to heavy rain, immersion, or more extreme conditions, you might want to consider devices with even higher IP ratings, such as IP66 or IP67, for added protection.

What is IP69K?

As per the IP rating system, IP69K computers and screens provide the utmost level of safeguarding for industrial equipment requiring high-pressure and high-temperature cleaning at the conclusion of a work shift. The IP69K test standard is extensively utilized in industries such as food processing, pharmaceuticals, and medicine. IP69K means the waterproof computer or waterproof display can endure intense sanitary cleanings without being damaged.

Benefits of IP69K

Uphold High Standards of Hygiene: IP69K HMIs are perfect for facilities that need to maintain their utmost cleanliness and require upholding high standards of hygiene. These industrial devices can withstand water and chemical exposure without compromising performance or reliability, thus upholding strict cleaning procedures.

Minimize Downtime: Industrial environments are often harsh and unpredictable, often causing system failures and downtime. A major benefit of the IP69K rated products is that they can withstand these conditions, which would prove fatal for electronic devices or instrumentation in most cases if not protected high levels of ingress protection.

Guaranteed Long-life Solutions: The IP69K rated enclosures can withstand high pressure jets and high temperatures which can often cause openings and ingress. Most IP69K solutions are made from aluminium or stainless steel allowing it to handle caustic solutions, meaning that the product will retain its reliability and guarantee a long-life. With this high degree of protection, costly repairs on industrial devices is prevented.

What Is The Difference Between IP69 and IP69K?

The German standard, DIN 40050-9, includes the letter K, expanding the IEC 60529 system with an IP69K rating for applications involving high-pressure, high-temperature wash downs. Enclosures with this rating are required to be not just dust-proof (IP6x), but also capable of enduring high pressure jets and steam cleaning. IP69K was designed for heavy-duty vehicles that require regular cleaning, such as concrete mixers, but it was adopted in various other sectors that demand superior hygiene and cleanliness, such as food processing.

Is IP69K Submersible?

While the IP69K rating indicates a high level of protection against water jets, it doesn’t necessarily imply that a device is submersible. The IP69K rating is specifically designed to test a device’s resistance to high-pressure, high-temperature water jets from various angles. Submersion protection is indicated by an IP67 or IP68 ingress protection, where the second digit (the “7” or “8”) indicates varying levels of water resistance, including the ability to be submerged to a certain depth for a specified period.

Stringent IP69K Test Specification

Products with an IP69K rating are subjected to rigorous testing to confirm their resistance to high pressure, high temperature water, and dust. Here are the following testing procedures carried out on our IP69K computers and IP69K displays:

- The system is positioned on a rotating platform that completes a full rotation every 12 seconds (5 rpm).

- The water pressure ranges from 1160 to 1450 psi.

- The nozzle is positioned 4-6 inches away from the device under test at 0, 30, 60, and 90-degree angles, each for a duration of 30 seconds.

- The system is sprayed with 80C (176F) water at a high flow rate of 15 litres (4 gallons) per minute.

Need Help Selecting an IP Rating for Your Application?

Tell us about your application and a member of our team will get right back to you.