Advantages of a Fanless Industrial PC and How to Install One

Fanless Industrial PCs provide multiple benefits to field engineers, system integrators and OEMs. Supporting versatile mounting options, compact form factors, more efficient power use, and rugged reliability in the field make them integral to a wide range of industries and applications whereby the environment they’re being deployed would induce frequent failures to a standard consumer grade PC. Integrating an Industrial Fanless PC in the field might seem like a simple procedure but there are some key considerations to make before installing your next Fanless Computer to best protect the system. Being subject to system downtime can bring essential business processes to a halt and cost much more than standalone replacement or onsite engineering costs for maintenance or repair.

Going fanless with your next Industial PC can bring many advantages in giving you a reliable and durable solution which will help you avoid being subject to machine failures and make you ditch the traditional tower PC for good. In this article we look at the key characteristics of Industrial Computing, how fanless technology works, the distinct benefits of utilising passive cooling versus using traditional fans for active cooling, and the best practices for installing a Fanless PC at the Edge.

What Makes a Computer Industrial?

There are three main characteristics to an Industrial Computer which separates itself from a consumer-grade PC:

- Designed and manufactured with various form-factors and mounting options for industrial applications.

- Ruggedized to easily manage demanding harsh environmental standards and avoid system failures.

- Long life availability as part of an embedded roadmap.

Form-Factors and Mounting Options for Industrial Applications

Industrial computers are available as either Box PC or Panel PC solutions. Choosing one or the other comes down to personal preference or simply whether you even need a display. These displays can also be integrated with added touch capabilities to create an Industrial All-In-One HMI. The advantage of an All-In-One Touchscreen Computer includes simplified installation inside an enclosure but can increase the cost of replacement should the system become damaged. Connecting an Industrial Box PC to an Industrial Monitor mitigates this risk by separating the two assets. Should either fail, only one part of the system needs replacing. Another advantage includes the option to upgrade should additional performance or connectivity be required in the future.

Industrial Box PCs can be installed to run headless without a display, or alternatively be connected to an Industrial Monitor. A typical Industrial Box PC would include options for wall mounting or DIN-mounting. Where wall-mounting might serve its purpose inside most industrial cabinets, DIN-mount PCs may be preferred for a simplified installation with added flexibility to easily reposition or move the PC. Mounting brackets can also include anti-vibration plates should the system be subject to shock and vibration, such as being installed next to heavy machinery or onboard rolling-stock such as vehicles or trains.

Capabilities To Withstand Harsh Environments with Rugged Specifications

Many industrial automation applications require computers that can withstand harsh environmental conditions. Some applications require going fanless with Dust-Proof Computers or even Waterproof Computers. Going fanless is the first step in creating a Rugged Industrial PC and is the best choice for operating in a dusty environment. When fans operate onboard a PC, they create a vacuum which sucks air through onboard vents to cool down onboard components and remove hot air built up inside the chassis. When bringing in this cooler ambient air from outside the chassis, other environmental airborne contaminants such as dust and debris also gets sucked inside the PC, this dust contamination can impede necessary air flow and degrade cooling capabilities to a point where a built-in mechanism called thermal throttling kicks in. This thermal throttling reduces the clock speed and overall performance of the PC in order to protect the CPU from overheating and damaging the system. Operating a consumer-grade PC in these environments over long periods of time will stress components to a point of early failure. The unique thermal designs of our Fanless Box PCs and Fanless Panel PCs remove the requirement for ventilation holes and threat of dust contamination.

When looking for a Fanless PC requiring an onboard GPU you have a couple of options. Standard practice for Industrial GPU Computers adopting a discrete graphics cards is to utilize a fanless PC design with a separate expansion cassette. Separating the PCI expansion cassette from the motherboard and components means that the system can remain fanless whilst adopting PCIe or PCI add-on cards for frame grabbers and graphics accelerators etc. Completely Fanless Edge AI Systems are also available with integrated MXM GPUs or NVIDIA Jetson whereby the onboard GPU is heatsinked with the chassis.

Some industrial applications such as clean room processing environments also have a requirement for computers to be subject to water. A Waterproof HMI is the preferred choice by system operators in these applications with a built-in display. When a IP65 or greater Panel Mount PC is mounted into an enclosure cut-out, a watertight seal is created. This means that the front bezel is protected from spraying water or disinfectants, allowing no ingress getting past to onboard I/O connectors at the back of the system. An Industrial Fanless Stainless Steel Panel PC is recommended to be deployed in food processing environments whereby the computer is subject to being frequently washed down or cleaned with chemicals as the stainless-steel chassis prevents rust and corrosion.

Extended Product Life Cycles with Long Term Availability

When integrating hundreds of industrial computers at the edge, field engineers and OEMs prefer to lock down a defined system bill of materials along with its operating system image which will guarantee reliability from the project offset. With projects lasting five to ten years, or more, having this protection from an Industrial Computer on the embedded roadmap guarantees a long-life solution and ensures future deployments to operate seamlessly.

Whereby consumer-grade hardware goes through frequent single component changes, or limited life cycle availability for 2 years, this can have a drastic knock-on effect with system compatibility from both hardware and software compatibility. Software and operating systems which were proven to work on one system may not operate correctly on the updated hardware iterations with alternate components onboard, this can pose a problem for industrial applications. If the software or OS no longer operates as required, a new software image may need to be created, which is never desirable as it increases time to deployment and system management complexity.

Industrial manufacturers of Fanless Industrial PCs will usually specify the launch date and number of years which the device will be available. This is typically in line with the onboard Embedded CPU which can also be found on the manufacturer’s website. Industrial Computers following the embedded roadmap are typically available on the market for 10 years without being subject to any component changes.

Fanless Industrial Computing For Edge Environements

What is Passive Cooling? How Fanless Industrial Computers Work

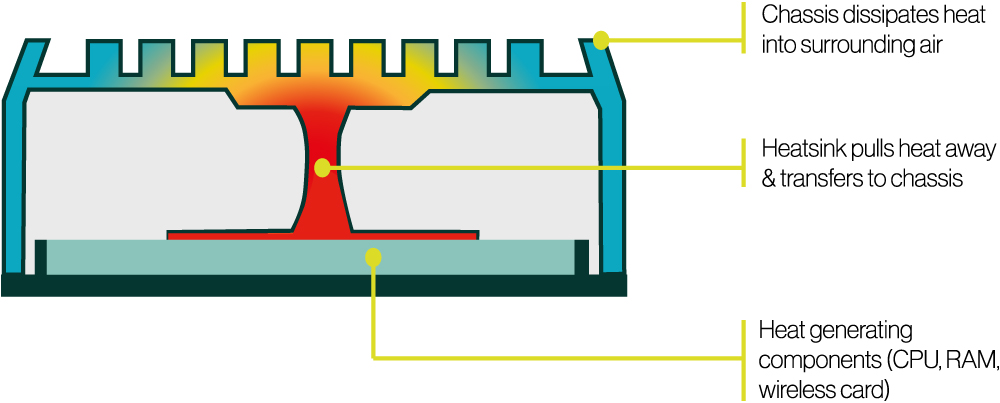

Actively cooled PCs utilising fans are not too dissimilar to Passively Cooled Computers. In a typical fanned PC, there is a large heatsink sitting on top of the CPU with a fan sitting on top or integrated inside. Modern day High-Performance Computers also host heatsinks and fans for other onboard components generating excessive amounts of heat, including GPUs, onboard memory, NVMe SSD storage and frame grabbers. Those heatsinks keep components cool by pulling heat away from the components by literally sinking into them. Through advanced heatsink designs and reduced power draw from components such as the CPU, the fan can be removed, putting full reliance on passive cooling.

To install a heatsink securely and guarantee a complete and functional thermal connection, a combination of thermal pastes or pads should be used to remove any imperfections from mating with the heat generating component. From here, the heatsink can be physically bolted to the industrial motherboard to prevent any dislodging when subject to shock or vibration.

This covers the basics of fanless cooling down to a component level, but now we have the complexity of hosting an Embedded Single Board Computer or Industrial Motherboard inside a chassis. Heatsinks still require enough surrounding air or a degree of airflow to move generated heat from building up too much. If for example you placed a single board computer with a heatsink inside a compact enclosure, all components inside the enclosure that are generating heat will cause the ambient temperature inside the enclosure to rise, in turn replicating the same problem of heat build-up you were trying to avoid in the first place. This heat needs to be spread as best as possible to the outside of the chassis or enclosure, which is how Fanless Industrial PCs operate. Heat spreaders are used to mate the heat generating components with the system chassis, effectively drawing the heat to the outside.

So, after using multiple heat spreaders to transfer thermal energy to the outside chassis, what happens to the heat? As described earlier the CPU heatsinks typical have integrated fans to operate as forced convection. Designing Industrial PCs with finned designs are purposefully made that way to benefit from natural convection which means they don’t have to rely on moving air to dissipate heat from the system. As hot air rises, this natural flow of air will push past the fin surface and remove heat from the vicinity. Installing the PC vertically will increase the surface area for air to pass naturally, more on this topic later in the article.

Benefits of Industrial Fanless Computers

Increased Levels of Ingress Protection

Did you know the most common point of failure for traditional tower PCs being installed in industrial environments is down to dust ingress and fans failing to actively cool the CPU?

The primary benefit of fanless computer systems in industrial environments is that they are resistant to dust and debris. Industry leading Fanless PC manufacturers design their Embedded PCs to be resistant to dust and debris by utilising passive cooled technology. Utilising onboard heat spreaders and chassis heat sinks allows them to create a closed system not requiring ventilation.

Removing onboard fans allows vents to also be eliminated. This is the first step in creating a Rugged Computer and allows systems to meet different levels of ingress protection to protect sensitive internal components from dust, debris and potentially water, all of which can wreak havoc on system reliability and cause failures in the field.

Most systems will carry an ingress protection rating of IP5x making the system protected from limited dust ingress. Choosing an IP6x specification makes the system completely dustproof. Should waterproof protection be required, specialist connectors would be required to prevent water ingress if the I/O is subject to getting wet. Click here to learn more about the importance of ingress protection.

More Durable Against Shock and Vibration

The second benefit of removing active cooling to create a fanless PCs is that they are much more resistant to both shock and vibration. Simply put, the less moving parts there are, the less things that can fail in the system. Traditionally, when removing onboard fans, the only moving parts left on the system were 2.5″ spinning disk hard drives. With advancements in SSD technology this no longer applies and achieving no moving parts onboard an Industrial PC is easily achievable.

Rugged Embedded Computer manufacturers and system integrators use a number of techniques to help the PC withstand continuous shock and vibration, such as:

- Thicker PCBs for onboard motherboards to reduce flexing and bending.

- Cableless design or better cable management to prevent any connectors from becoming loose.

- Rugged I/O and power connectivity with locking or latching connectors.

The ruggedized capabilities of any system are validated with approved testing standards for anything from light industrial use to military deployment. Extreme Rugged Computers can withstand up to 50G shock and 5GRMs vibrations with the MIL-SPEC-810G conformity.

Higher Reliability and Less Maintenance

Industrial Edge Computers are required to operate reliably with complete stability around the clock, 24/7. The costs associated with a failure in the field can soon mount up, whether that’s increased engineer costs for system maintenance and repair or replacing failed hardware. Times this cost of repair and replacement by potentially a thousand systems deployed in the remotest areas, and you’ve got a large bill for ongoing operation costs.

Removing the onboard fans from your computer prevents dust and debris from entering your systems. A fan which is clogged with dust and debris can cause the component to overheat and fail, in turn putting heavier stress on the onboard CPU causing it to consistently throttle or in the worst-case scenario, fail. Using passive cooling eliminates the possibility that you will experience any downtime due to a failed fan and reduces the requirement for onsite maintenance.

Enables Compact Low-Profile Footprints

The compact and lightweight design of industrial fanless computers makes them a great choice for deployment in small spaces such as electronic cabinets and onboard vehicles. Fanless Low Profile Computers are available with reduced height designs because they don’t need be actively cooled with an onboard fan. Utilising heatsink technology therefore allows onboard components to be fitted closer together whilst still providing sufficient cooling, which means that these computers take up less space. The compact footprint of Fanless Mini PCs allows them to easily be mounted in extremely tight places such as cabinets, enclosures, or on the underside of tables. A Compact Fanless Mini PC would typically have a footprint no larger than 20cm x 10cm whereas an Ultra Compact Fanless Mini PC could easily fit in the palm of your hand.

Energy Efficient with Lower Power Consumption

Have you considered the ongoing operation costs on the overall deployment of your edge computing fleet? Fanless Industrial Computers give you the added benefit of consuming less energy than their consumer-grade counterparts. This isn’t just from the reduced power overhead of operating a fan for active cooling but using alternate lower power embedded processors. This reduced level of power not only reduces the overall heat generated by the computer, allowing for efficient operation with passively cooled heatsink technology, but also reduces the overall running cost of the PC.

Although the power savings from a single PC can be deemed relatively negligible, if you are deploying a thousand systems simultaneously as part of your IoT deployment, you will notice significant savings on energy costs. (A/1000) x B x 24 x 365 x C is a simple equation to calculate the total power consumption over the course of a year; where A is the total CPU watts, B is the cost of power per kilowatt hour, and C is the total number of systems.

You shouldn’t be worried about system performance either as lower power processors don’t necessarily mean the overall performance of the system will be drastically reduced, if at all. This article explains CPU TDP (Thermal Design Power) in depth and gives you a key understanding to understanding power vs performance.

Silent Operation

A final and notable benefit of fanless computers is they have the ability to run silently because they do not use fans to cool the system down. Capable of not producing any audible noise might not reduce the risk of failure but it does makes them perfect for deployment in areas where silent operation is important. Applications to utilize Silent Fanless Mini PCs include Digital Signage, Operating Theatres, Onboard Vehicles etc. Since SSDs do not have any moving components, they are a key component in allowing the system to run silently.

How To Install a Fanless PC

Though Industrial PCs are built to more rugged specifications, our Fanless Computers are as easy to integrate and set up as an off the shelf consumer-grade PC. Once installed and operating, the system should be warm when touched. This is a good side that the passive cooling mechanism is working and doing its job effectively. Using infrared technology, you can take a temperature measurement from the chassis to make sure the dissipated heat isn’t excessive as this can indicate an issue and may cause your CPU to throttle. If for example the external surface temperature of the heatsink exceeds the datasheets specified operating temperature for the IPC, you should assess your installation.

Efficient Cooling Requires the Fanless PC to Be Installed the Right Way

Fanless cooling is dependent on both efficient internal conduction and external convection. This is known as passive cooling, and it allows heat to dissipate from internal components to the external cooling fins. Allowing for proper airflow over the external cooling fins is critical for fanless cooling to work efficiently. In some use cases for high-performance PCs, external fans are used to assist with moving cooler air over the chassis to aid in system cooling.

When installing a Fanless Computer in a fully enclosed location, such an unventilated cabinet in a manufacturing environment or in the trunk of a vehicle, ambient temperatures can soon climb beyond the ambient temperature of its surrounding environment. Even though our Fanless Cooling PCs are very efficient, allowing adequate space around the system for air to pass over the fins will also help ensure optimal performance. If your project is subject to installing in a compact enclosure you should remember that heat rises and make sure no other heat-producing equipment is located below the PC. There should also be adequate airflow above the PC to allow air to pass over the heatsink fins and allow for natural heat convection. Stacking additional equipment, whether heat-emitting or not, will inhibit cooling capabilities and may cause CPU throttling or potential system damage over time. On the subject of heat rising, you’ll get optimal cooling performance if the heatsink fins on the Industrial PC are facing upwards when installing on either a horizontal or perpendicular surface. If required, Fanless Computers can be installed on the top of an enclosure with the cooling fins facing downwards but optimal cooling efficiency will be impacted, and this should be monitored closely.

Keep In Mind Environmental Factors from Ambient Temperature Swings to Dust, Debris and Water

Although nearly all of our fanless PCs are much more likely to withstand environmental contaminants, they are not all built the same. In order to optimize system performance and guarantee a long-life solution the correct level of ingress protection should be chosen. This will help best shield the PC from debris whether this is dust, water or another contamination found in your environment.

Another key component of ingress protection is driven by the selection of onboard I/O. Where most fanless PCs utilize standard connectors such as RJ45 for Ethernet or DB9 for Serial, optional port blocking kits are available to enhance the systems capability of protecting itself from ingress. Where this may not improve overall system reliability it could prevent a port from malfunctioning or requiring increased maintenance to clear them from any debris.

An alternative option for increasing ingress protection is to select a Rugged Embedded Computer which hosts M12 circular locking connectors. These are a de facto standard when a Waterproof Computer is required, or alternatively an increased level of protection from shock, vibration or potential cable snagging is required. More information about industrial M12 waterproof connectors can be read up on here.

Solar gain is also often overlooked when installing a Fanless Outdoor Computer. Solar gain is the increase in temperature caused by solar radiation which can add up to 90W per square foot of thermal load. Regardless of whether the sun shines on the Outdoor Computer, or down onto an enclosure with the Fanless Computer inside, this increases the systems temperature and should be monitored accordingly.

Use A Dedicated Power Supply

It is important to use the computer’s own power supply whenever possible and keep its input independent from other equipment. By avoiding sharing a common DC source with any inductive load such as that from solenoids, relay switches, motors etc, you mitigate risk from devices which can create backwards voltage spikes which can damage or destroy computers. If looking to utilize the same power supply, you should verify that the Industrial Computer has the required DC power protection. Some AC power supplies with your Fanless Computer may provide the electrical protection not built in as a standard specification to the PC. Rugged PCs tend to feature wider power input ranges which are also capable of withstanding dips or surges in power. Typical DC input for these types of systems is wide ranging from 9 to 48V DC, compared to a fixed 12 or 24V DC input on a standard industrial PC.

Looking For an Industrial Fanless Embedded PC?

Tell us about your application and a member of our team will get right back to you.