Key Features for Choosing a Sunlight Readable Display

When outdoors on bright and sunny days you may have noticed that it’s difficult, if not impossible, to view the display or HMI that you’re trying to operate. This is primarily for two reasons; a lack of screen brightness and reflections off the outer protective glass. To combat poor visibility in environments with a high ambient brightness a sunlight readable monitor is recommended. Also known as hi-bright or high brightness monitors, these displays are designed specifically for use in direct sunlight and bright ambient conditions.

This guide will help you make an informed decision on your next commercial or industrial touchscreen outdoor display with the best design specifications found in sunlight readable displays.

Improve Readability with Our Commercial and Industrial High Bright Displays & HMIs

High Bright Panel PCs

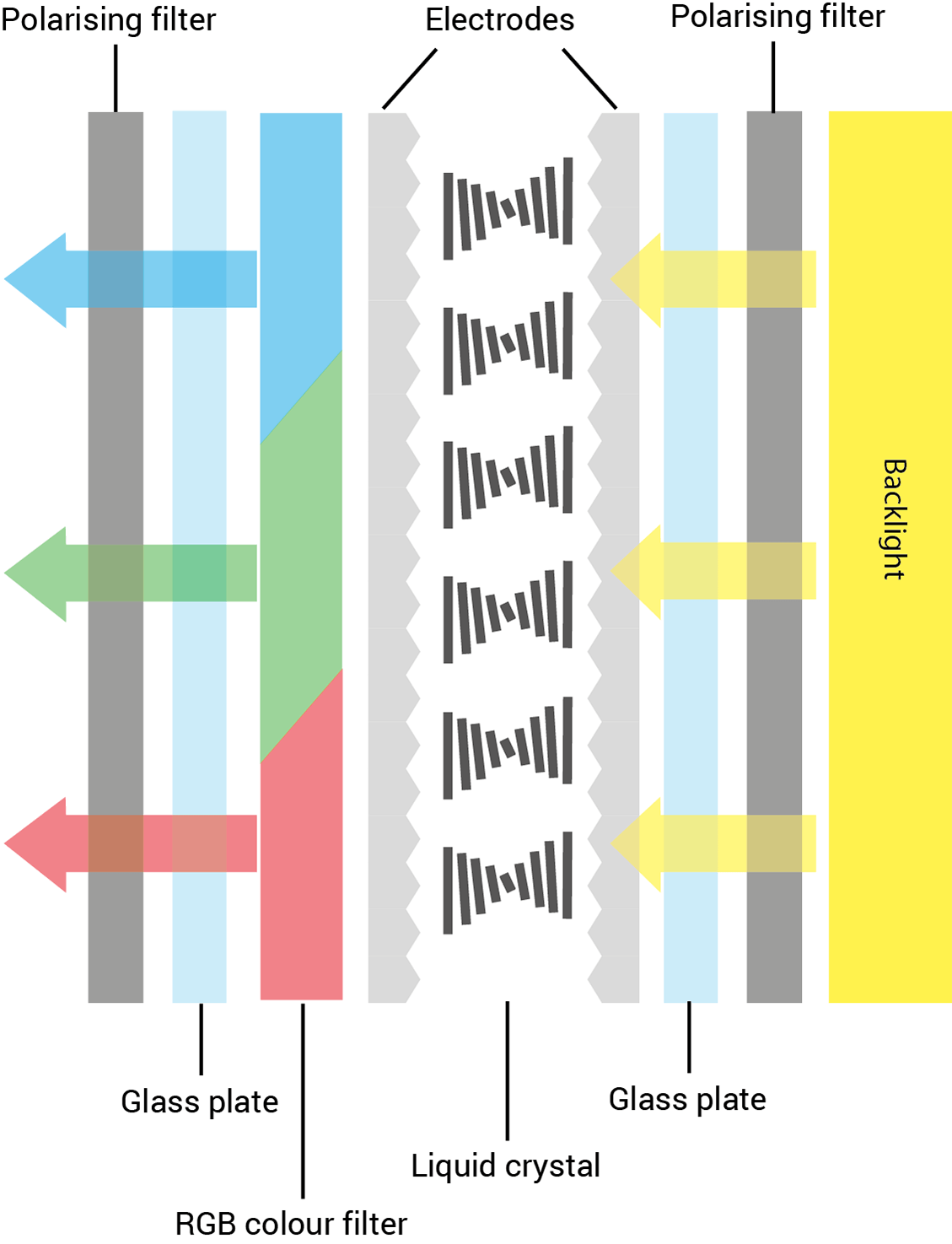

A Visual Representation of an LCD (Liquid Crystal Display)

LCD technology is widely adopted in commercial and industrial applications as it is superior in terms of price to quality ratio. Traditionally illuminated by fluorescent tubes, most LCD displays in the market today use Edge LEDs or LED backlights for illumination. Below you will see the layers behind an LCD display before being overlaid with protective glass or a touch overlay.

Advantages of LCD Technology

- High brightness options up to 6,000 Nits

- High level of detail with resolutions up to 8K

- Good balance of brightness and contrast

- Low power consumption

How is Screen Brightness Measured?

When comparing display specifications from different manufacturers you may come across the brightness metrics known as NITS and cd/m2 . These are both measurements of how bright the LED backlight source is and will give you an understanding for the type of environments in which the display can be deployed, more on that later.

Understanding Candela, or CD/M2

Candela is a now outdated brightness metric that is based on traditional “whale oil candles.” 1 Candela is the light emitted by one whale oil candle and cd/m2 represents the candela per meter squared.

Introducing NITs

NIT is the now standard metric for measuring luminance, which is how much light an object emits. It comes from the Latin Nitere, which means “to shine.” The display brightness measurement in NITs is the equivalent to candela, or cd/m2, but is not officially part of the International System of Units.

1 NIT = 1 cd/m2

CD/M2 and NITs can therefore represent the same thing and can be used interchangeably, you will see this across our datasheets for high bright sunlight readable displays.

Recommended Screen Brightness for Industrial Display Applications

Night-time Marine Bridge

For marine bridge operations between the hours of dusk until dawn, the ambient brightness typically falls below 250 nits. In such conditions, maritime regulations mandate the use of a display setting with a brightness of 1 nit. This stringent requirement ensures optimal visibility for mission-critical applications, while also minimizing interference with the night vision of the ship's crew, thereby prioritizing safety and navigation accuracy during nocturnal voyages.

Indoor With Light

In indoor settings illuminated with moderate lighting, displays often encounter an ambient luminosity of around 1,000 nits. For such environments where light conditions are manageable, it's advised to set the display brightness to a level of up to 300 nits. This calibrated brightness is particularly ideal for situations such as in building and surveillance monitoring setups. Ensuring the right brightness in these controlled light scenarios not only guarantees clear visibility but also promotes efficient monitoring and data interpretation.

Bright Shops and Industrial Factory Floors

In bright shops and industrial factory floors, where ambient lighting is intensified, displays often encounter luminosity levels ranging from 1,000 to 3,000 nits. To cater to such high-bright indoor settings, it's suggested to adjust the display brightness to a level up to 500 nits. This recommendation is specifically tailored for locations that benefit from augmented indoor lighting but doesn't extend to areas in close proximity to windows, where external light could significantly elevate the ambient brightness. Such optimal brightness levels are particularly crucial in settings like point of sale stations or bustling industrial shop floors to ensure that the displayed content remains clear, readable, and efficient in guiding or informing users.

Overcast Sky or Indirect Sunlight

For environments with an overcast sky or indirect sunlight, the ambient brightness typically ranges between 3,000 to 7,000 nits. In such settings, a display brightness of approximately 750 nits is advised. These brightness levels are particularly suited for displays positioned indoors near windows or in semi-outdoor locales, like public transport stations and stops that are sheltered.

In Window Displays & Direct Sunlight

When dealing with in-window displays exposed to direct sunlight, the ambient brightness can surge to levels between 7,000 to 10,000 nits. To combat this intense luminosity and maintain optimal visibility, it's crucial to adjust the display brightness appropriately. For these settings, a brightness level ranging from 1,000 to 3,500 nits is advised. Especially in the realm of digital signage, where image clarity and the ability to view content from afar are paramount, a more luminous screen ensures the displayed information stands out, unaffected by the sun's glare. It's particularly pertinent to opt for the higher end of this brightness range for screens that are south-facing and continuously bathed in direct sunlight, ensuring that they remain both clear and legible at all times.

Outdoor Displays & Direct Sunlight

Outdoor displays that are continuously subjected to direct sunlight encounter an ambient brightness of around 30,000 nits. To ensure that these screens remain clear and legible in such intense light conditions, it's crucial to select a brightness level that lies between 3,500 to 6,000 nits. Such brightness levels, among the highest available, are indispensable for retaining impeccable image clarity and viewability in the great outdoors. When setting up screens in locations particularly vulnerable to the relentless beams of direct sunlight, it's advisable to opt for the maximum brightness possible without compromising on image quality. Alongside, choosing a high TNI panel becomes essential to further enhance the display's resilience and visual performance.

Sunlight Readable Displays can be Dimmed at Night

Most industrial displays and all-in-one computers with sunlight readable LCDs are available with an optional auto-dimming characteristic. If the brightness of the sunlight readable display becomes overwhelming at night or when there is little or no ambient light, then the brightness can be changed. Integrating an ambient light sensor on the front bezel which measures incoming light can automatically adjust the backlight brightness to match the current light conditions.

What is Sunlight Readable display technology?

There are several technical approaches and various enhancement methods to increase screen viewability and reliability in the sunlight. The primary enhancement is to develop a backlight system that increases the brightness of the LCD to overcome a brightly lit environment. There are also other technologies that can be added to a high bright backlight including optically bonding the display, transflective enhancement, direct backlighting with local dimming, and applying anti-reflective or anti-glare coatings.

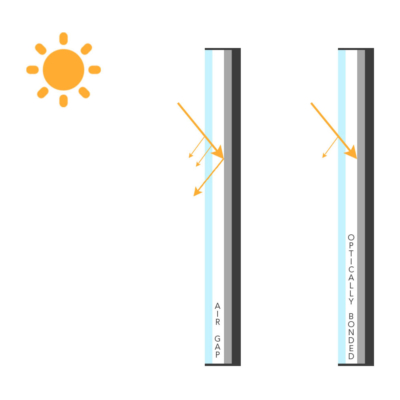

Optical Bonding to Reduce Refraction

Optical bonding is a process where a layer of resin is applied between the glass or touchscreen and LCD panel of a monitor, bonding them to make a solid laminate with no gaps or pockets of air.

When an external source of light hits the screen the gap between the glass and LCD module creates opportunities for refraction which bounces external light back off the screen to the viewer as glare. If optical bonding is applied the light passes through the bonded layers and is absorbed somewhat into the screen. Optical bonding therefore helps in making screens sunlight readable and can replicate a higher bright display with better levels of contrast.

Transflective Enhanced LCDs

An alternate method for minimizing backlight heat and improving outdoor viewability is to enhance the LCD with a Transflective, meaning transmissive-reflective, layer. This transflective layer allows the ambient light to be reflected through the LCD display and redirects the sunlight to make the LCD viewable in a high bright ambient environment. This allows for lower power displays with high performance colour enhancement in outdoor environments.

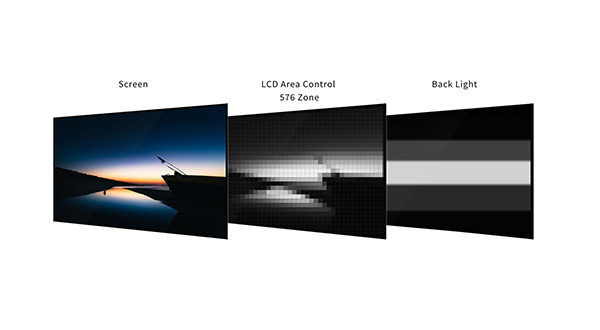

Local Dimming to Reduce Heat and Save Energy

Local dimming is a technology which dims the LED backlights within controlled zones to optimize brightness and contrast, reduce heat generation and save energy. This is achieved by placing several small LEDs to illuminate the screen over a smaller area when compared with the entire surface. With the “Local Dimming” function certain areas of the image can be blacked out and others illuminated – thus creating a very high and dynamic contrast ratio.

High TNI LCD Panels Prevent Displays Blackening Under the Sun

LCDs are susceptible to high heat and UV radiation. Over time, UV radiation from the sun can cause LCD screens to degrade with the UV damaging the LCD panel. This will lead to the point that they can produce an unacceptably poor performance. In order to help prolong the onset of such damage, UV and IR band filters and mirrors can be used to minimise the amount of damage.

A high TNI liquid crystal panel is designed to prevent blackening when the sunlight readable display operates under elevated temperature conditions. This includes not just outdoors where there is direct sunlight and high ambient temperatures but also where displays are embedded and airflow is limited creating a build-up of heat within the enclosure. A primary application would be in window displays or outdoor kiosks.

High TNI panels support surface temperatures from 80°C up to 110°C which prevents the display from blackening under the sun. This is a big increase when compared with standard operating temperatures of a normal panel being rated to 50°C as standard.

The embedded LCD display behind shows typical blackening effect from high surface temperatures when not using a high TNI panel.

High MTBF Figures and 16/7 or 24/7 Display Operating Times

Most of our industrial and commercial sunlight readable monitors and designed for operation 16/7 (16h per 7 day) at a minimum, so they can be easily handle long shifts each day of the week. Some models are even suitable for 24/7 continuous use, so you can use these displays around the clock. This is interesting for signage applications and use in shops if the high bright display should play content around the clock.

Our range of high brightness monitors are filterable by size, mounting type, ingress protection and key vertical markets for which they are suitable. Alternatively speak to one of our technical sales engineers about your application and we will make some recommendations.

Need Help Choosing A Sunlight Readable Monitor?

Tell us about your application and a member of our team will get right back to you.