Understanding GMSL Technology for Industrial Edge AI

Gigabit Multimedia Serial Link (GMSL) was first created by Maxim Integrated in California. Following the company’s acquisition by Analog Devices in 2021, the technology has continued to thrive worldwide. While it was originally intended for automotive use, GMSL is now widely adopted in many other fields, including automated guided vehicles (AGVs), collaborative robots (cobots), autonomous mobile robots (AMRs), as well as agricultural and off-highway equipment.

High-speed data transmission is a cornerstone of edge AI computing, where platforms like NVIDIA Jetson process vast amounts of real-time sensor input for advanced decision-making. Gigabit Multimedia Serial Link is a critical video interface technology that enables low-latency, high-bandwidth transfer of high-resolution camera and sensor data directly to Jetson-powered systems. With support for multi-stream sensor fusion, GMSL ensures reliable performance across complex AI workloads at the edge. Its rugged design and long-distance capabilities make it ideal for industrial and automotive deployments.

“GMSL is a high-performance, high-speed interface recognised for its high data rates, low latency, and reliability, making it especially valuable in automotive and robotics applications. While features such as Power-over-Coax bring clear benefits, complex system and software integration remain a significant challenge. We work closely with both industrial edge AI computer and camera manufacturers to simplify this integration and help customers accelerate their time-to-market.” Andrew Whitehouse, Managing Director at Things Embedded

Key Advantages of GMSL Technology for Edge AI

Many of our customers adopt GMSL because it provides a proven way to connect multiple high-resolution cameras and sensors to edge AI systems without sacrificing performance or reliability. In applications where real-time data processing is critical, such as robotics, industrial vision, autonomous vehicles, and advanced monitoring, GMSL ensures that video and sensor data can be transmitted with precision and stability, even in challenging environments.

The success of GMSL comes from a combination of strengths including high data rates, low latency, low power requirements, full-duplex operation, and strong data integrity, all of which make it a reliable choice for demanding applications.

GMSL, GMSL2 & GMSL3 - High Data Rates with Low Latency

The original GMSL standard enabled multi-gigabit data transmission with low latency, establishing the foundation for real-time sensor applications. Its successor, GMSL2, increased bandwidth to 6 Gbps while retaining low power and robust performance. The latest generation, GMSL3, doubles this again to 12 Gbps, providing even greater capability for transmitting high-resolution data in sensor fusion and other real-time systems. This makes it possible to transmit high-resolution sensor streams for real-time applications. The technology is particularly valuable in sensor fusion, where inputs from multiple high-resolution cameras, along with radar or lidar, must be transferred, combined, and processed simultaneously by a single processor.

Reduced Cabling with Power-over-Coax (PoC)

GMSL simplifies cabling by transmitting video and power over a single coaxial cable using Power over Coax (PoC), allowing sensors such as cameras to be powered directly without separate wiring. With GMSL2 and GMSL3, the same link can also carry control commands, synchronisation signals, haptic and touch data, software updates, and status messages, while supporting duplex communication through serial protocols like SPI and I²C. By efficiently utilising bandwidth, GMSL achieves very low latency and enables high-resolution camera support at high data rates, reducing system cost, improving reliability, and extending service life since cables and connectors are common points of failure.

Reliable Connectivity for Cameras and Sensors up to 15 Meters

GMSL technology supports transmission distances of up to 15 meters over a single coaxial cable, providing exceptional flexibility in system design. Cameras and sensors can be placed well away from the host processor without any loss in data rate, frame rate, or latency, which is critical for real-time vision and sensor fusion. This extended reach allows engineers to cover larger areas with fewer processing nodes, reduce the need for additional cabling infrastructure, and position sensors in locations that are optimal for safety, visibility, or performance. In applications such as robotics, autonomous vehicles, industrial inspection, and smart agriculture, the ability to reliably transmit high-resolution video and control data over long distances lowers integration complexity and increases overall design freedom.

Pairing GMSL with an Industrial Edge AI Computer

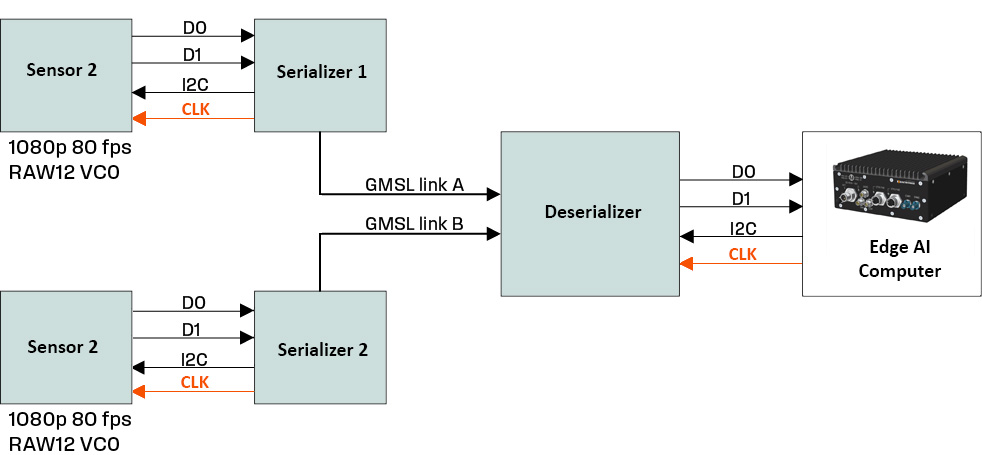

Because high-resolution video carries such large amounts of information, it is typically compressed before transmission. A serializer (SerDes) takes the parallel data from the sensor and converts it into a high-speed serial stream, which is then transmitted in packets over the cable. At the receiving end, a deserializer (Des) reconstructs the packets back into their original parallel form so the embedded computer can process the data correctly. Once received, the video can be used in applications such as driver assistance, precision agriculture, environmental monitoring, or autonomous navigation.

Despite its many strengths, GMSL also presents certain challenges. Compared with more straightforward interfaces like USB or Ethernet, system integration is more complex. Developers often face hurdles when working with the Virtual Channel framework, as it requires careful attention to both hardware configuration and software integration, along with a solid understanding of the underlying technology.

It is essential that the serializer and deserializer are matched, meaning they must come from the same product family to ensure proper operation. The deserializer must also be compatible with the host processor that handles the data. Processing can only continue if the processor supports the required output format, such as MIPI-CSI. The next sections outline these challenges in greater detail.

I²C Addressing and Proxy Addresses

When multiple sensors and serializers share the same physical I²C address, unique proxy addresses must be assigned. The deserializer handles this dynamically at runtime, preventing address conflicts and ensuring clear, unambiguous communication.

Virtual Channels

Virtual channels allow multiple video streams to be carried in parallel over a shared CSI interface. Each stream is assigned a dedicated virtual channel ID, which must be properly configured on both the sensor and the receiver to guarantee correct mapping and error-free transmission.

Device Configuration via Device Tree

Proper configuration of the device tree is essential for system functionality. It defines elements such as CSI lanes, bandwidth settings, power supplies, and the precise mapping of components. Errors in this setup often prevent camera streams from being received and can lead to lengthy troubleshooting.

Synchronization and Timing

Using multiple sensors at the same time demands precise synchronisation, particularly when they share a single CSI port. Mismatched lane configurations or asynchronous modes of operation can result in data loss or misinterpreted signals. This may cause issues such as image flicker during scene transitions or reduced image quality from poor sensor calibration.

Looking to Integrate GMSL Into Your Next Edge AI Computer?

Our team at Things Embedded can help you choose the right industrial edge AI computer and camera solutions, streamline integration, and reduce development time.