Choosing an Embedded Motherboard or Single Board Computer

When looking to embed a computing platform into a device, machine or enclosure there are some subtle differences between consumer-grade or hobbyist boards when compared to embedded or industrial-grade compute platforms which shouldn’t be overlooked. Without being immersed in the embedded industry and knowing the challenges of different industrial applications, understanding these key specifications and choosing an industrial motherboard or embedded single board computer can be a time-consuming and difficult task.

Essentially both single board computers and motherboards are printed circuit boards that host all the necessary components of an embedded computer. Traditionally, a single board computer would differentiate itself from a embedded motherboard by having all components soldered on a single circuit board, however, the need for flexible expansion by integrating additional PCBs such as memory, storage, I/O, or connectivity muddied the waters. Here at Things Embedded we differentiate a single board computer to a motherboard by its form factor and generally whether it hosts a socketed or soldered onboard CPU. A list of various form factors for both embedded SBCs and rugged motherboards fit for industrial applications are later listed in this article.

Industrial embedded boards are primarily selected to be installed as part of an embedded system which is used to perform a specific task or function. OEMs, system integrators and field engineers integrate boards in various form factors with industrial grade components for a variety of use cases, such as:

- Controlling touch screen kiosks.

- Automating process manufacturing.

- Promoting content through digital signage.

- Improving patient healthcare solutions.

- Deploying artificial intelligence in unmanned systems.

The need for computers within harsh industrial applications proved particularly challenging and created a market for ruggedized motherboards which are robust, durable and flexible. This guide should help you gain a deeper insight into the advantages of an industrial embedded motherboard or single board computer, understand key specifications found onboard our range of embedded computing or industrial computing solutions, and ultimately guide you in validating a cost-effective solution which gives you reliability and longevity in the field. Of course, our technical engineers can help you choose by making some recommendations.

Embedded Single Board Computers and Industrial Motherboard For The Edge

Advantages of Industrial Motherboards and Embedded SBCs

To begin, we’ll start with three key advantages of industrial motherboard and embedded single board computers when compared to commercial solutions.

Durability and Reliability

When product and project managers are looking to incorporate boards in harsh and unforgiving environments, durability and reliability ratings are a key specification which can define how long the solution would last in the field, if at all. Being prone to dusty or inclement atmospheres, extended operating temperatures, repeat shock and vibration, or variable power can be extremely detrimental to the performance of a standard computer not utilising industrial components or best configuration practices. All it takes is one point of failure, and if a computer platform doesn’t meet all the requirements to withstand such factors for which it is to be deployed in, these types of harsh environments would make the computer subject to system downtime, or worse yet, system failure. Industrial SBCs and motherboards are available with wide operating temperature thresholds, enhanced fanless heat dissipation through either heat spreader or heatsink technology, protection against shock and vibration, and support for fluctuating power with wide voltage AC or DC inputs. In short, industrial boards are built to last and require little, if any, maintenance during the duration of their implementation.

Embedded Roadmaps and Supply Continuity

Non-industrial motherboards available in the commercial market can rapidly become obsolete after as little as 2 years. This is stemmed from rapid advancements in technology whereby the consumer wants continuity in increased levels of performance down to a component level. Since the industrial marketplace is built on a fit for functionality mindset, a bill of materials is typically defined at the start of the project and intended to last for the lifecycle of the product or intended application. When releasing new chipsets, manufacturers typically provide a life cycle of 10-15 years as part of their embedded roadmap. This guarantees the availability of that particular chipset or component and allows embedded and industrial manufacturers of embedded and industrial PC platforms to guarantee availability for the same period of time. Having this longevity in availability allows for simple field replacements or continued rollout over extended periods of time without worrying about next generation hardware replacing legacy systems and having compatibility issues arise with either hardware or software.

Cost Effective Solutions

Another commercial imperative when releasing a new product into the market or integrating a solution to carry out a specific task in the field would be cost. When deploying a new board level computing solution there are two costs associated: upfront cost for purchasing the hardware, and ongoing running costs. Motherboards and single board computers embedded for industrial use are designed to be cost-effective from both standpoints. Flexibility in both COTS availability and large volume manufacturing can reduce the level of board components to give you everything you need, and nothing you don’t. This also applies to system performance, after all why install an Intel Core system when Intel Pentium for example may be suffice. When compared with power-hungry commercial PCs, industrial variants typically require less power in aid of reducing running costs, allowing deployment in wide temperature environments, and most importantly allowing for fanless operation in harsh environments subject to ingress, a common point of failure.

Is Your Motherboard or SBC Rugged Enough for Edge Deployment?

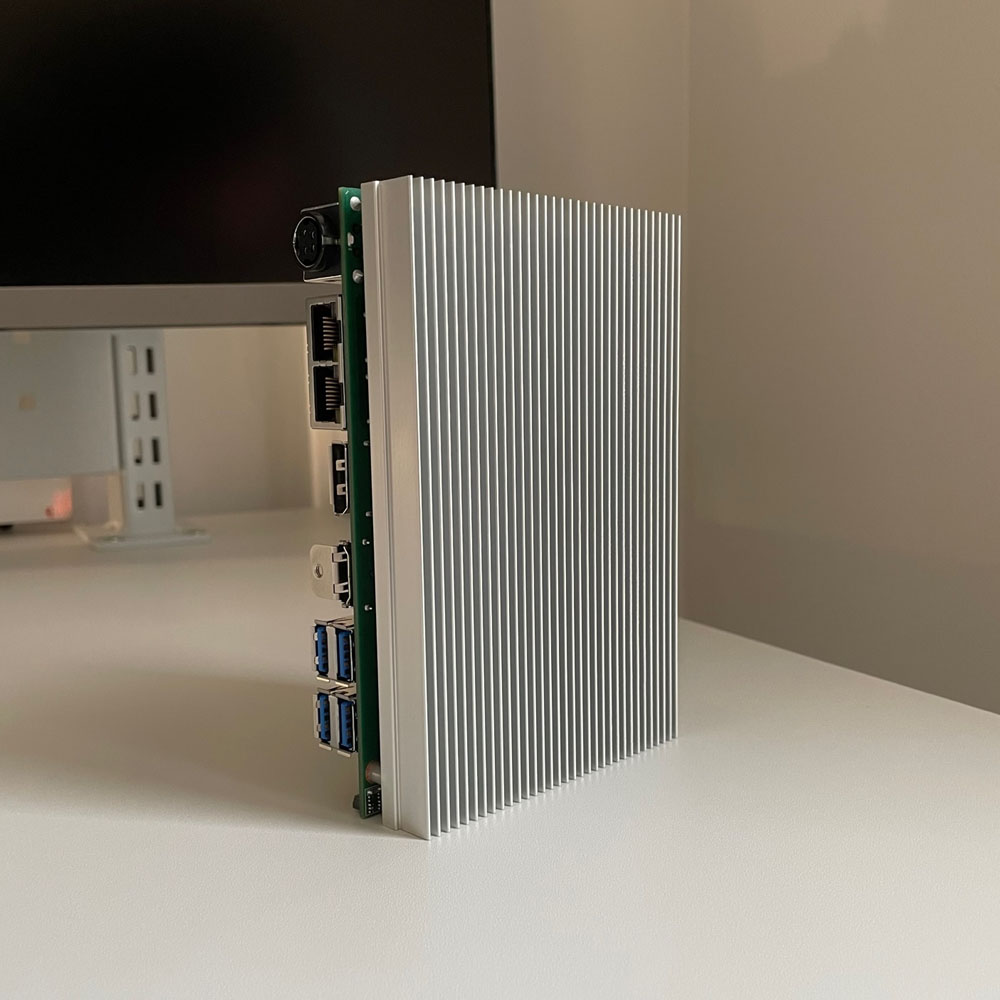

Going Fanless: Heatsink or Heat Spreader

With fanless embedded PCs being in the market for a long time now you may be familiar with different heatsink designs to keep the system cool enough under load. Higher performance computers require larger heatsinks with fins to maximise the surface area and spread the heat accordingly, this is known as passive convection cooling.

Heatsinks are also adopted by single board computers and industrial motherboards to spread the heat generated by the CPU and keep them cool enough to operate accordingly without having to throttle. Other components onboard might also require some assistance in passive cooling if generating large amounts of heat, such as video capture cards and even some new high-speed NVMe SSDs.

Heatsinks still require enough surrounding air or a degree of airflow to move generated heat from building up too much. If for example you placed a single board computer with heatsink inside a compact enclosure, all components inside the enclosure that are generating heat will cause the ambient temperature inside the enclosure to rise, in turn replicating the same problem you were trying to avoid in the first place. This heat needs to be spread as best as possible to the outside of the chassis or enclosure, similar to how fanless box PCs operate.

Heat spreaders are mated to the exterior surfaces. Through conduction, the aluminium heat spreader dissipates heat evenly to the surface of which it is bonded to. Embedded Computers rely on heat spreaders to dissipate heat from the CPU to the heatsink as part of the systems chassis. Heat spreaders are typically available with most Embedded Single Board Computers and can be easily designed and manufactured for bespoke use cases.

Hot & Cold Temperature Tolerances

Designed to be embedded as part of a larger subsystem, whether inside a system chassis or control cabinet, airflow is either greatly limited or completely restricted for fanless operation. Factors such as heat generation from board level components such as CPUs and GPUs can cause the temperature inside the chassis or cabinet to rise much greater than the ambient temperature outside the chassis or cabinet. For this reason, an increased temperature tolerance should be considered on the upper band of supported operating temperatures. If your factory floor has an ambient temperature of 50°C, you should not consider a solution supporting operating temperatures of 50°C as being suitable if embedding a computer into a cabinet, particularly a high-performance power-hungry platform. A common wide temperature board will support 70°C which will give you the extra tolerance you require.

Manging colder environment extremes are much more manageable and the only consideration should be for cold start-ups. This means the computer will boot from the lowest possible temperature and not just ‘continue to operate’ after start-up should the temperature drop during system operation. A common wide temperature board will support -20°C and will guarantee cold system start-up in an ambient temperature of -20°C.

Deciding on Performance, Expansion with Storage or Connectivity, and Critical I/O

Energy Efficient or High Performance

Energy efficiency is one of the key primary benefits when choosing single board computing. It is important to benchmark your application when integrating a new Embedded PC as it helps gauge a system’s ability to run applications reliably. Comparing benchmark CPU scores will allow you to benefit from lower power CPUs without sacrificing on adequate performance for the application.

CPUs are built on either RISC or CISC architecture. Arm Single Board Computers are RISC (Reduced Instruction Set Computing) based, and Intel x86 Single Board Computers are CISC (Complex Instruction Set Computing) based. Comparatively, x86 Computing offers many more instruction sets which in turn leads to better performance at an offset of more power consumption.

In modern day computing, the lines between RISC and CISC are a little more complex as both ARM and Intel adopt ideas from one another. Multi-core processors are now developed on architecture variations from one another.

I/O Plates & Board Level Connectors

Industrial boards are connected to a wide range of sensors, IIoT devices, peripherals, displays etc. The source of your data, peripherals, and available bus types will typically define your projects required I/O and ultimately the required footprint for an embedded computer. Depending on the space you have available to integrate an industrial board, you may have to compromise on the type of connector available on board. It is important to check the datasheets and confirming the connector type available for all required ports along with the supported technology to guarantee it also carries enough bandwidth.

You may be familiar with an I/O plate as it is standard on larger format PCBs such as industrial motherboards. Embedded single board computers also adopt standard I/O plates but also include various onboard connectors. In some cases, daughter boards are also required for breaking out additional connectivity with high density connectors, this is common as part of a PC/104 stack. The smaller the SBC, the number of ports available for the most common connectors such as DB9 for Serial, Type A or Type C USB, or even RJ45 for Ethernet will be reduced.

When utilising board level connectors, it is worth noting the additional measures required when fixing your bill of materials. A custom cable assembly will have to be engineered by either yourself or your SBC distributor. As this creates added complexity it can increase your projects timescale to deployment and create additional unforeseen lead times on the continued rollout.

Embedded vs Standard Display Connectors

Some installations for single board computers and industrial motherboards are completely headless, meaning they don’t require a display output to carry out the designated tasks when deployed in the field. Other use cases require the embedded computer to be paired with a display, or in some use cases multiple displays. Where standard I/O plate display connectors such as VGA, DVI, DisplayPort and HDMI are relatively straight forward connections, they also take up a lot of retail space on board, particularly if requiring multi-display capabilities. Another limitation to the standard display outputs is the capability for interfacing with a TFT LCD panel display which use embedded display connectors. TFT LCD panel displays are a common choice for machine builders or OEM product design and manufacturers for complete control over custom aesthetics and continued reduction in overall cost of build.

A standard TFT LCD display panel commonly utilise embedded display connections such as LVDS (Low Voltage Differential Signalling) or eDP (Embedded Display Port). Since its introduction in the 1990s, LVDS has been the de facto standard for video input from most of the major TFT LCD manufacturers. The newest standard, eDP, carries some advantages for OEMs over LVDS being a fully digital interface and is now commonly being supported by the latest industrial SBCs to market. Benefits of the modern eDP standard includes a much higher signal bandwidth allowing for higher resolutions and higher refresh rates whilst supporting a lower power consumption. Cable assemblies are also simplified with eDP vs LVDS as they require a significantly reduced number of high-speed wire pairs for any given link rate.

Expansion for Storage and Connectivity

Much like checking the datasheet for I/O connector types and supported interfaces, the same applies for small form factor expansion such as mPCIe and Next Generation Form Factor M.2 standards. Connector types can be shared between the desired expansion card and host motherboard whilst the supported Bus technology differs, making it incompatible.

A common example of this is for mPCIe expansion. Although this is transitioning to be a legacy expansion, mPCIe is still common for connectivity expansion cards such as Wi-Fi and Cellular, these mPCIe slots can also be used for storage in the form of mSATA SSDs. Whereas Wi-Fi or Cellular would utilise PCIe or USB signals from the mPCIe expansion slot, an mSATA SSD would require SATA signals to be supported. The latest available small form factor M.2 expansion is a little more complex with its available card form factors, keys and Bus support but carries distinct advantages in its compact footprint including support for higher bandwidths simply by utilising more PCIe lanes. Here is an in-depth article about available slots, keys and supported Bus standards via M.2 expansion.

Types of Embedded Single Board Computers

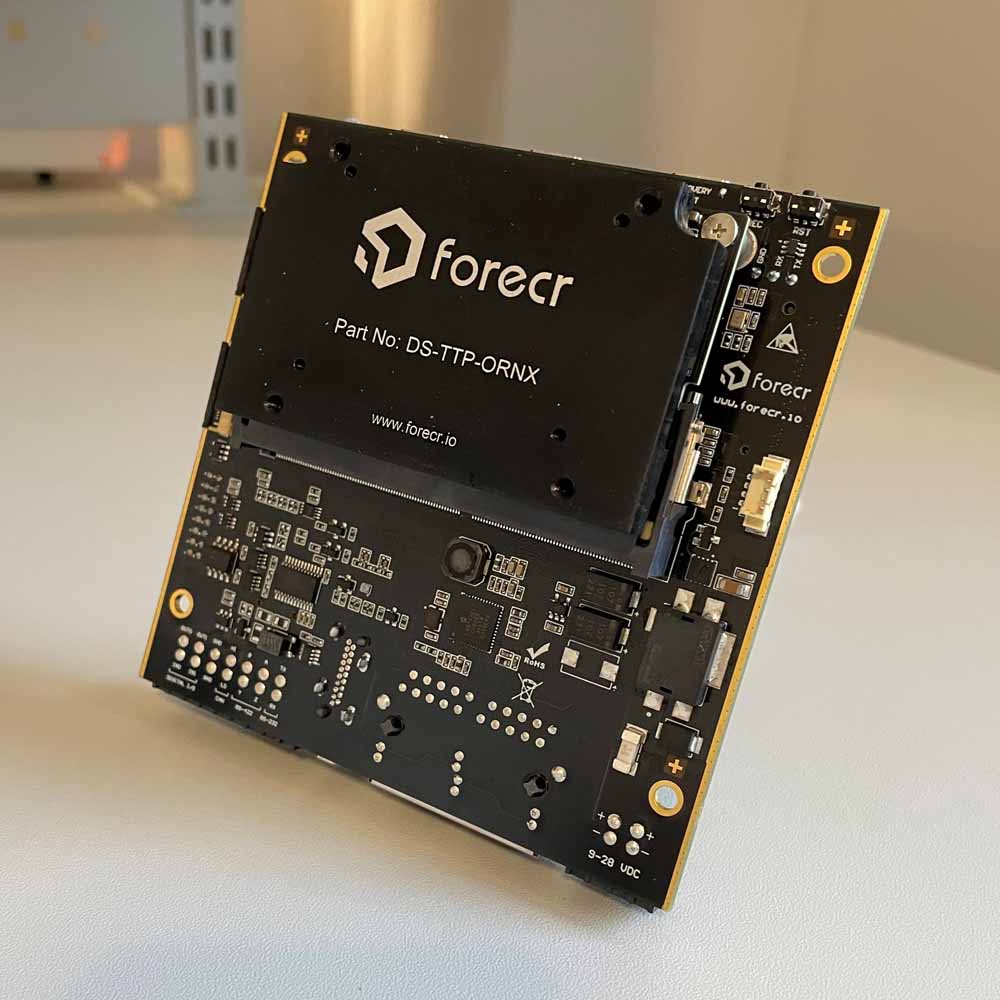

1.8" Femto ITX Single Board Computer

Known for its ultra-small and lightweight form factor, the industrial 1.8” Femto-ITX Single Board Computer delivers robust power in the most compact footprint for intelligent edge computing for IIoT applications. Available with both energy-efficient and high-performance CPUs onboard, typical specifications include a couple LAN and USB with M.2 or mPCIe expansion onboard for connectivity or extending onboard eMMC storage.

Size: 84mm x 55mm (3.31″ x 2.17″)

2.5" Pico-ITX Single Board Computer

The original standard for a compact embedded single board computer, the industrial 2.5″ Pico-ITX Single Board Computer offers a broad I/O layout to cater for a multitude of applications. It is common to find a wide range of board level headers for flexible expansion whilst remaining suitable for integration in space limited installations.

Size: 100mm x 72mm (3.94″ x 2.84″)

3.5" Single Board Computer

Industrial 3.5″ Biscuit Single Board Computers are full featured solutions for a variety of industrial uses with adequate space on board for an increased level of memory, I/O (LAN, USB, COM, Display Ports), and expansion via mPCIe, mSATA, or M.2 bays. Most 3.5″ SBCs are available with a heat-spreaders or heatsinks to allow for fanless active cooling whilst maintaining capabilities to operate in wide or even extended operating temperatures.

Size: 146mm x 101.7mm (5.75″ x 4″)

4x4 Single Board Computer

The original four-by-four ‘Next Unit of Computing’ NUC Single Board Computers by Intel deliver incredible performance with a wide range of soldered-on processors. Based on a mini 4×4″ PCB these embedded boards deliver incredible power density and are also available as fanned and fanless mini box PCs. With integrated and discrete graphics onboard, support for Intel Core i3, i5, i7 and i9 CPUS, and carrying all the essential I/O, the Intel NUC platform is ideal for light industrial applications and very popular in digital signage and broadcasting.

AMD Ryzen Embedded is also available on a 4×4″ SBC with a range of low power high performance CPUs with incredible graphics performance capable of supporting multiple displays.

Size: 104mm x 102mm (4.09″ x 4.02″)

PC/104 Single Board Computer

PC104 Single Board Computers encompasses a range of different buses and pin-outs, from the original PC104 to PC104-Plus, PCI-104, PCI104 Express, and PCIe104. Being around for over 30 years this form factor is largely integrated in both rugged industrial and military applications. These cards are typically used in a stacked configuration making it ideal for high expandability in tiny footprints. Already hosting a wide range of I/O in board level connectors, OEMs design their own peripheral boards where specialized functionality is required. These solutions get their name from the 104 pins that are used to connect the cards together.

Size: 90mm x 96mm (3.55″ x 3.78″)

Types of Industrial Motherboards

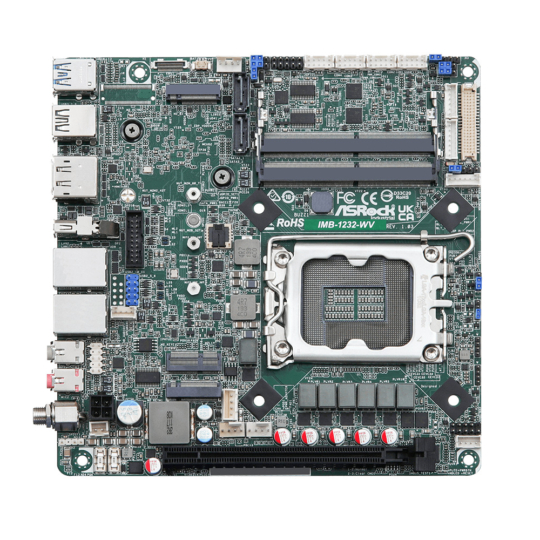

Industrial Mini ITX Motherboard

Industrial Mini-ITX Motherboards are the most common footprint and offer a number of advantages when compared to both large and small board level computers. Small enough for space constrained applications or installing as part of a Small Form Factor Box PC, the Mini-ITX can host high performance desktop CPUs for both fanned active cooling and passive cooling through a heatsink. With the latest onboard multi display graphics, the form factor is large enough to fit multiple display outputs along with other popular I/O such as COM ports or USB. Industrial Mini-ITX Motherboard manufacturers have established themselves in the embedded ecosystem for over 20 years delivering a multitude of highly configurable solutions with long lifecycle availability. Thin Mini-ITX Motherboards are also available for low profile applications where available height for installation is at a premium. Typically, this hosts a reduced heigh I/O plate.

Size: 170mm x 170mm (6.7″ x 6.7″)

Industrial ATX Motherboard

Known for its rich I/O and vast capability in expansion, Industrial ATX Motherboards can support multiple PCIe or legacy PCI cards, making them ideal for industrial automation applications.

The ATX footprint is also available in Industrial Micro ATX Motherboard and Extended ATX Motherboard form factors. While Micro ATX Motherboards support up to four PCI/PCIe lanes, the extended variant can support up to seven lanes. Some standard ATX chassis support the EATX Motherboard but are typically suited for integration in a rack-mount chassis.

Size: 305mm x 244mm (12″ x 9.6″)

Intel Embedded vs AMD Embedded Boards

Embedded boards are integral to many of the technological advancements in various industries, from healthcare to entertainment. They require specialized processors that are optimized for performance, power efficiency, and size. Two dominant players in this market, AMD Ryzen and Intel, offer unique solutions for embedded motherboards and Single Board Computers. Their respective product lines have their own distinct characteristics and advantages, catering to different embedded application requirements.

AMD Ryzen Embedded Boards

AMD's Ryzen Embedded boards have made significant strides in the embedded market. Designed to offer high-performance computing and remarkable energy efficiency, Ryzen boards are available in a range of options, catering to various application needs. Their strong multi-core performance makes them suitable for applications that require intensive computational work, such as gaming, medical imaging, and industrial systems. Moreover, Ryzen's embedded chips are celebrated for their robust graphical capabilities, allowing for seamless visual rendering. With scalability and flexibility at its core, AMD Ryzen SBCs continue to be a prominent choice for developers looking for powerful yet efficient embedded solutions.

Intel Embedded Boards

Intel's portfolio for embedded motherboards and SBCs is vast and diverse. Products such as the Intel Atom and Core processors are specifically tailored for different market needs, ranging from IoT devices and industrial automation to networking equipment. Intel emphasizes integration, with various processors designed to work smoothly with different I/O options, providing the flexibility needed for compact and energy-sensitive applications. Furthermore, Intel's advanced power management techniques help in maintaining a balance between performance and energy consumption. With a long-standing presence in the market for embedded boards, Intel remains a trusted choice for developers, focusing on providing versatile and reliable solutions that can adapt to the ever-evolving technological landscape.

Looking To Eradicate Failures with Your Next Board Level Integration?

Tell us about your application and a member of our team will get right back to you.