Benefits of Remote On/Off Functionality in Vision Computing

The ascent of edge computing has brought a variety of advantages to manufacturing, such as flexibility and decentralisation. A few drawbacks of deploying mass amounts of inference PCs are network lag and the deficiency to access a device or equipment if it is powered off.

Remote on/off allows you to turn devices on and off using a remote command from another device when utilised with a computer or server. Such signals can come from an online framework, timer, sensors, or user input. This article quickly introduces some of the strengths and weaknesses of remote I/O and explains how distant on/off functions add worth to industry systems like automation and machine vision purposes.

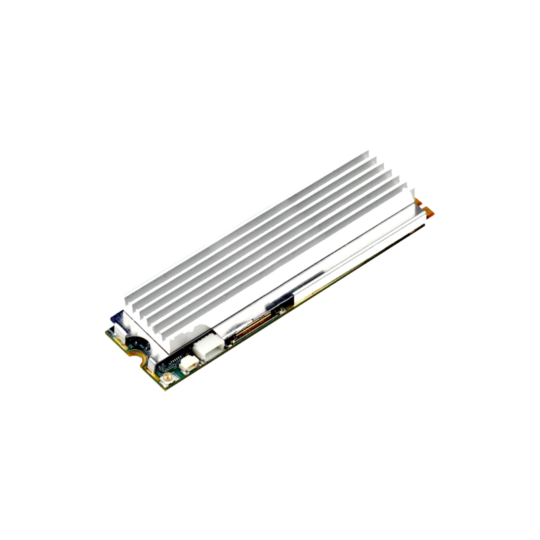

At Things Embedded we provide fully-configured industrial computers with distant on/off operations alongside other edge devices with distinct advantages for improving response time when extracting data at the edge. Our toolkit for implementing artificial intelligence in machine vision applications includes GPU-enabled edge servers, IoT devices, and image-processing frame grabbers.

Fully Configured Edge AI Computers and Devices

Ethernet & USB Frame Grabbers

Innovating with IIoT and AIoT at the Edge

Through AI development and advancement in data sources such as neural networks and machine learning models, industries continue to innovate with the Industrial Internet of Things (IIoT) and Artificial Intelligence of Things (AIoT) for a wide range of vision-based applications. Here are a few notable applications that demonstrate how computer vision and machine vision are innovating a wide range of industry applications:

Autonomous Vehicles: Improved warehousing and last-mile delivery services.

Smart Surveillance: Improvements in security, critical infrastructure, and asset monitoring

Smart Cities: Automatic tolling systems, traffic monitoring, and access control.

Logistics: Handling materials, mail and package sorting, and order fulfilment.

Quality Control: Real-time inspection of factory process control lines.

Medical: Assisted surgical robotics, medical imaging, and other healthcare diagnostics.

As edge computers and devices become more intelligent and connected, remote features are evermore essential for transferring large data packages dependably without failure. Fast, reliable, and redundant connections are key to success for remote safety I/O and machine vision systems. Remote I/O continues to help expand edge infrastructure with Ethernet I/O taking a lead role in reducing the amount of required wiring whilst providing faster processing speeds.

The advancement of industrial control systems for machine vision means newer and more sophisticated edge systems are need to be developed so that more data can be rapidly transferred to keep up with applications that require H.264/H.265 video decoding and real-time inference. The capabilities of many Programmable Logic Controllers (PLCs) may not be able to keep up with the speed required for advances in vision computing, resulting in a slow down of operations.

For vision and AI applications requiring inference at the edge we recommend using a high-performance AI computing with a system like the EAC-5000 from Vecow. This edge AI computer hosts the latest Jetson Orin Series modules from NVIDIA and delivers up to 275 TOPS of AI performance in a fanless envelope.

How Remote On/Off Helps Machine Vision

In order to conserve bandwidth, only the essential data is transmitted across the network. Any complex or large pieces of information are processed near the device instead of relying on cloud computing. Bandwidth can be saved by reducing the size or volume of information packages. Applications that require faster speeds and more data transfer, like machine vision and connected devices, greatly benefit from the addition of remote on/off features.

Device sequencing or on/off switching is possible with remote on/off. A network may experience slowness or use more bandwidth if several sensors are constantly delivering data. Remote On/Off can shut down a device before another is powered on to limit bandwidth consumption and reduce lag.

The same remote on/off concept can be applied to connected sensors. A motion detector and an IP camera are two examples of devices that can use remote on/off to make sure that only one of them is operating at any one moment. When a certain inspection does not pass, a camera is activated to capture a picture of the failure, triggered by a sensor that signals the failure. The IPC will simply toggle from the sensor to the camera to document an image of the failure with the relevant metadata. This data could then be sent to the cloud for review.

Why Remote On/Off Makes Sense for Security, Control, Flexibility and Scalability

Remote On/Off functionality built into industrial PCs for machine vision makes sense for a host of reasons including security, control, flexibility and scalability:

Security: Digital connectivity increases accessibility, but it can also compromise security because gadgets are frequently left on so they can be accessed remotely. Devices can be powered down and protected from unauthorized access when not in use by utilizing the remote on/off capability, which conserves power and network resources. Security profiles can be employed to ensure the safety of the device without sacrificing availability.

Control: The remote on/off capabilities offer a way for applications to be controlled or accessed when a person is not present. It enables users to power devices, including motors, from a distance, based on pre-set times, programming, sensors, or user-defined data-sets. This helps to push the boundaries of technology and give greater command from a distance.

Flexibility: Technology can make old systems more adaptable but disrupting an infrastructure that is already in place can significantly increase the time and expense needed to install that new technology. Remote on/off can provide a retrofit or brownfield solution without requiring a change to the current infrastructure.

Scalability: A IIoT or AIoT pilot project for implementing machine vision at the edge may be successful. Increasing the number of linked items and solutions can lead to more intricate and more intensive network usage. The ability to turn devices remotely on and off will help decrease delays and maximize bandwidth by allowing users to only operate a single camera or device at once, and by providing the option to switch these items off when not necessary.

Things Embedded offers a selection of industrial computers that are powering industrial applications like edge AI and deep learning. These computers have different connectivity choices, bandwidths, speeds, and capacities. To find out how remote on/off can help your application or for any help with edge AI computing or general vision computing questions, drop an enquiry below.

Have an Edge AI Vision Computing Application?

Tell us about your application and a member of the team will get right back to you.