What Are Embedded Computers? Examples For Industrial Applications

What Is An Embedded Computer?

An embedded computer is a specialised box PC that serves as an essential component within a larger machine or system, playing a pivotal role in driving efficiency and innovation across numerous industries. Unlike a regular desktop computer, an embedded computer is typically designed or intended for specific functions such as control and automation, or inference and decision making. Regardless of whether the term embedded computer is unfamiliar to you, it’s highly likely that you’ve interacted with one at some point, perhaps even today. They are omnipresent and serve as the unseen core of everyday electronic devices we encounter and utilise in our daily routines. From ATM kiosks to self-checkout systems, smart highway signage to passenger information systems onboard trains, these systems are likely controlled by an embedded computer, possibly one of our own.

“Deploying computers at the edge brings a number of challenges which can be overcome using a system intended for its application and environment. One prominent hurdle is the limited installation space they typically operate within, necessitating compact dimensions, effective heat dissipation, and versatile mounting methods to accommodate diverse environments. Another critical aspect is the requirement for continuous and stable operation around the clock, especially in industrial settings like production lines, navigation systems, and monitoring equipment, where downtime could result in substantial losses. Moreover, these computers are often required to operate in harsh conditions, facing extreme temperatures, vibrations, and electromagnetic interference, demanding robustness and shock resistance to prevent system failures. The need for long-term supply is also paramount, as industrial equipment utilising embedded computers must remain operational for a decade or more.” Andrew Whitehouse, Managing Director at Things Embedded.

Things Embedded system design engineers possess years of expertise in providing solutions for industry with both COTS and custom capabilities. They have been involved since the initial conception of box PCs, delivering thousands of fanless embedded computers, and more recently, embedded computers equipped with onboard GPUs capable of artificial intelligence at the edge. Our System Engineers have extensive knowledge in choosing an embedded computer suitable for a wide range of applications, irrespective of the environmental conditions. Our website offers an extensive selection of embedded computers which can be fully configured and imaged to exact requirements before dispatch. Through our longstanding partnerships with leading global manufacturers, we can provide access to even more options not currently listed. These embedded computer companies are hand-picked and sit at the forefront of embedded computing design and manufacture.

Advantages of Embedded Computer Systems

Original equipment manufacturers (OEMs) and machine builders have consistently incorporated our embedded computers into their systems for a wide range of advantages. In contrast to their commercial equivalents, the components utilised in embedded computers are designed to last for an extended period, following a clearly outlined roadmap. OEMs and machine constructors need to have confidence that any component they incorporate into a system will be accessible for several years, hence, embedded computer manufacturers make sure this roadmap is transparent and strictly followed. Here are seven advantages of embedded computer devices:

Task Specific: Embedded computers are highly focused on specific tasks, which allows them to perform exceptionally well. They are designed to do one thing really effectively and efficiently. By concentrating all their resources on that one task, they can respond quickly, work with minimal delays, and use power wisely. Initially, embedded computers were designed to execute a single task or function. But, with the ongoing progress in computers and technologies like hybrid CPU architecture, AI acceleration, and 5G edge deployments, embedded computers have become significantly more potent, capable of supporting numerous functions and managing more intricate and intelligent tasks. This has led them to progressively become the propelling force behind IIoT and automation.

Cost-Effective: An Embedded Computer System offers a cost-effective solution through optimised system design. By tailoring hardware and software components to meet specific task requirements, these streamlined systems minimise unnecessary features and complexity. This targeted approach not only enhances performance but also reduces production costs and power consumption.

Form, Fit, and Function: Another reason why Original Equipment Manufacturers (OEMs) and machine builders opt for embedded computers is due to their form, fit, and function. Consider a scenario where an OEM machine, equipped with an embedded computer, has been operational on a factory floor for several years, and there’s a need to upgrade the chipset to support a new operating system being rolled out across the company. If all the I/O is extended to the exterior of the casing, it becomes crucial to find a direct substitute for the embedded computer that can meet the same I/O and housing needs. This is also relevant for new versions of an OEM machine, where the design might be updated and technology enhanced, but the I/O needs to stay consistent. A upgraded variant of the embedded computer with the same size or form factor can simply be procured and installed, which helps in cutting down R&D time and overall expenses. Options for mounting that are typical to embedded computers, but not found in their desktop or commercial counterparts, such as DIN-rail and VESA mount, provide greater flexibility for installations in control cabinets or within machinery.

Adaptable With Legacy Hardware: Connecting the old and the new is a common requirement for advancements in Industry 4.0. Expansion alternatives from the past are more easily accessible in embedded computers, like PCI, enabling OEMs and machine manufacturers to adapt older expansion cards as required. Legacy display outputs are also frequently compatible, with VGA remaining common in industrial and embedded applications, largely due to the durability of the connector and the widespread use of older display terminals.

DC Power Input: An embedded computer, which can be situated deep within an OEM system, often features wide ranging DC power input with remote on/off or ignition sensing capabilities. This allows for power cycling without the need to access control panels or completely shut down the system power. This enables the use of a single power supply in a control cabinet, powering not only the embedded computer but other peripheral devices also.

Built For Demanding Environments: Computers embedded at the edge are intentionally designed to endure the conditions to which they are subjected. From basic fanless embedded computers to ruggedised embedded computers with waterproof designs, our industrial-grade embedded systems are stripped of unnecessary components, adopting a lean and efficient architecture that enhances reliability while minimising points of failure. Embedded computers can endure exposure to extreme temperatures, moisture, dust, and vibrations. This resilience ensures seamless operation, consistent performance, and complete reliability in demanding conditions such as industrial settings, outdoor installations, and remote locations.

Long-Life Solutions Protected By Embedded Roadmaps: Embedded computers are designed with longevity in mind, following established embedded roadmaps that ensure their availability for extended periods. These roadmaps outline the lifecycle of the embedded hardware, software, and components, allowing industries to plan and implement long-term solutions with confidence. By adhering to these roadmaps, our embedded computer partners commit to maintaining supply, support, and compatibility over years, even in rapidly evolving technological landscapes.

Fanless Embedded, Industrial Embedded, or Rugged Embedded

Our customers come from diverse industries and often require a specific type of embedded system tailored to their unique operational needs. When selecting an embedded computer, it’s crucial to consider the environmental conditions it will operate in. Questions such as the expected temperature range, exposure to vibrations or shocks, presence of dust and other particulate matter need to be addressed. Additionally, factors like the available mounting options and power supply stability play a key role in decision making. By thoroughly assessing these conditions, you can ensure the chosen embedded computer is designed to withstand and perform reliably, aligning with the application’s longevity and performance needs.

Opting for an embedded computer which exceeds the applications requirements can lead to overpaying, whereas selecting an embedded computer that falls short of the application requirements, can lead to compromised performance, increased maintenance costs, and potential system failures. With hundreds of choices available in our tool-kit, we can often narrow down their requirements by starting to choose whether we need a Fanless Embedded Computer, Industrial Embedded Computer, or Rugged Embedded Computer.

Fanless Embedded Computers

Our fanless embedded computers are specifically designed for applications that prioritise low maintenance and reliability. These computers are the perfect choice for industries where uninterrupted performance is crucial, as they eliminate the risk of fan-related failures. By removing the need for a fan, these computers offer a seamless and reliable performance that is not hindered by potential fan malfunctions or breakdowns. Furthermore, our fanless embedded computers require minimal maintenance. Without a fan, there are no moving parts that need regular cleaning or replacement, reducing the overall maintenance requirements and costs. This makes them an ideal choice for applications such as installing inside kiosks where downtime and maintenance disruptions need to be minimized.

Industrial Embedded Computers

In industrial settings, the emphasis on robustness and compatibility is of utmost importance. This is because industrial environments often involve harsh conditions and the need for seamless integration with existing machinery. As a result, there is a strong preference for industrial embedded computers that can withstand these challenging conditions and seamlessly integrate with the existing infrastructure. One key feature of industrial embedded computers is their ability to operate in a wider range of temperatures, allowing it to be installed in a control cabinet with limited venitaltion. Another important feature of industrial embedded computers is their increased I/O (Input/Output) or expansion availability. Industrial automation machinery and control systems often requires a wide range of inputs and outputs to communicate with various sensors, actuators, and other devices.

Rugged Embedded Computers

A rugged embedded computer from Things Embedded ensures reliability even in the most challenging environmental conditions. Designed to be exceptionally sturdy, these computers are built tough to be shielded against shocks, vibrations, extreme temperatures, and various forms of ingress like dust and water. Constructed using a solid-state design with secure locking I/O and industrial-grade components rated for extended operational temperatures, our rugged embedded computers are ideally suited for demanding embedded and industrial applications at the edge. These applications include scenarios such as construction sites, mining operations, marine environments, outdoor installations, as well as mounting onto heavy machinery or onboard vehicles.

Embedded Computers For IIoT & Edge AI

The introduction of the Industrial Internet of Things (IIoT) and Artificial Intelligence (AI) has revolutionised industrial applications by enabling unprecedented levels of connectivity, efficiency, and intelligence. Things Embedded support a wide range of industrial sectors integrate IIoT and Edge AI to streamline operations. We help manufacturing companies optimise production lines for better efficiency and quality control, agriculture companies benefit from real-time data analysis to enhance crop yields, energy companies implement predictive maintenance on their smart grids, and transportation or logistics companies achieve real-time tracking and efficient route planning. The combination of IIoT and Edge AI, known as Artificial Intelligence of Things (AIoT), proves pivotal across these sectors, enhancing productivity and innovation. Our range of IIoT Gateways and Edge AI Computers are utilised by some of the world’s largest companies across various industries and applications. These computers are designed to seamlessly integrate within all vertical markets for industrial applications.

IIoT Gateways

The 'Industrial Internet of Things' refers to the network of interconnected devices that can communicate and exchange data with each other. By incorporating IIoT capabilities into embedded computers, we enable them to connect and interact with various other devices and systems within an industrial setting. This connectivity allows for real-time monitoring, data collection, and analysis, leading to improved decision-making and operational efficiency. Focusing on data processing, these gateway devices are ideal for edge applications that necessitate minimal computational capacity, IT and OT protocol compatibility, and cellular or Wi-Fi connectivity.

Edge AI Computers

Our embedded computers with GPUs or AI Accelerators leverage the power of 'Artificial Intelligence' to optimise their performance. AI algorithms and machine learning techniques are integrated into these GPU-accelerated computers, enabling them to learn from data, make predictions, and provide inference with automated processes. This AI-driven automation helps in reducing human intervention, minimising errors, and increasing productivity. Our range of NVIDIA Jetson computers have gained prominence due to their compact design, processing power, and suitability for deploying AI algorithms closer to the data source at the edge.

Embedded Computer Examples For Industrial Applications

Furthermore, our embedded box computers are available with in-vehicle, rail, marine, medical, ATEX or Class 1 Division 2 certification right off the shelf. We also have the capability to certify general purpose products according to specific industry standards. This enables us to assist you in building your integrated system without any concessions.

Automation PCs

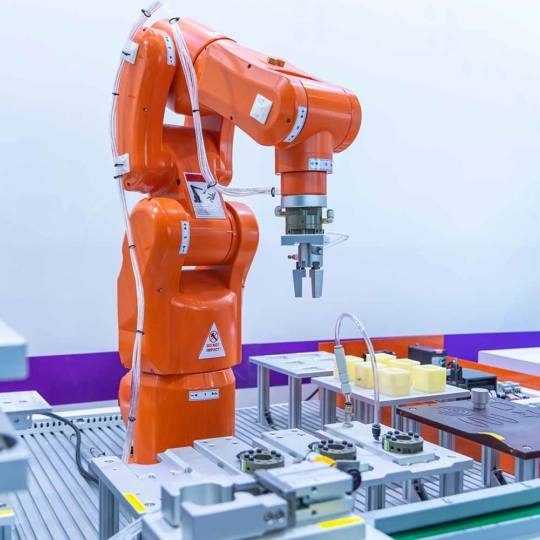

Automation PCs streamline and optimise various automated processes in industrial settings. Equipped with high-speed communication protocols to interface with cameras, sensors, actuators, and other machinery, they play a pivotal role in controlling and monitoring complex manufacturing, assembly, and production processes. Sectors such as manufacturing and logistics integrate our robotics computers for greater precision, efficiency, and consistency, while minimizing human intervention.

Vehicle Computers

Onboard vehicle computers need different types of connectivity for advanced functionality. Cellular connectivity allows real-time data transmission, Wi-Fi enables local data exchange, and GPS/RTK provides location information with high accuracy for applications like autonomous driving. Additionally, the UN ECE Regulation 10 (E-mark) certification ensures electromagnetic compatibility and electrical safety of automotive electronic components.

Rail Computers

Rail computers provide edge computing functions for signal control, monitoring and detection of the railway infrastructure, and passenger infotainment systems in trains, to ensure train safety through data collection and real-time control. Standards such as EN 50155 establish criteria for electronic equipment used on rolling stock, encompassing aspects like temperature, shock, vibration, and electromagnetic compatibility. Other standards like EN 45545 focus on fire safety requirements.

Mission Computers

Mission computers play a pivotal role in military applications by providing robust and advanced computing capabilities for mission critical operations. Built to rugged standards with specialist circular MIL connectors, our military computers are untouched by extreme temperatures, shock, vibration, and electromagnetic interference. Certifications such as MIL-STD-810G for environmental ruggedness and MIL-STD-461F for electromagnetic compatibility are often applied to guarantee they can perform under stress and adhere to stringent standards.

Medical Computers

Medical PCs often facilitate diagnostic imaging tasks, enabling the visualisation and interpretation of medical scans like X-rays, MRIs, and CT scans. They also support telemedicine and remote patient monitoring, connecting patients with healthcare providers for virtual consultations and real-time health tracking. Certification found onboard our medical PCs include IEC 60601-1, UL 60601-1, and EN 60601-1-2. These international standards outline safety and performance requirements for medical electrical equipment, ensuring patient and operator safety.

Digital Signage Computers

Categorised as 'light-industrial', digital signage computers are generally installed in a less harsh environment. They continue to uphold all the industrial standards such as long-life availability, but don't necessitate extensive temperature capabilities or a plethora of I/O. The primary focus is on more high-resolution display outputs, and a compact or slimline design is frequently preferred to allow the system to be accommodated behind digital signage screens or inside a kiosk.

Partner With A Leading Embedded Computer Supplier

If you want to learn more about the advantages embedded computing, or would like us to recommend a solution, simply tell us about your application, and a member of our team will get right back to you.